Tool Steel : 1.2316 / X38CrMo16

Product Details:

- Application Mold steel, Cores, Inserts, Mold cavities, Automotive, Industrial, Manufacturing, etc.

- Material Tool Steel

- Click to view more

Tool Steel : 1.2316 / X38CrMo16 Price And Quantity

- 5000 INR/Number

- 500.00 - 5000.00 INR/Number

- 1 Number

Tool Steel : 1.2316 / X38CrMo16 Product Specifications

- Tool Steel

- Mold steel, Cores, Inserts, Mold cavities, Automotive, Industrial, Manufacturing, etc.

Tool Steel : 1.2316 / X38CrMo16 Trade Information

- Letter of Credit at Sight (Sight L/C), Cheque

- Yes

- Contact us for information regarding our sample policy

- Central America, North America, South America, Eastern Europe, Middle East, Asia, Western Europe, Australia, Africa

- All India

Product Description

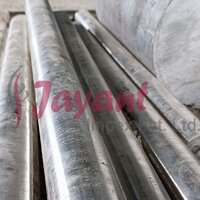

1.2316 Alloy Steel Round Bar, X38CrMo16 Rods, Bars (Normalised, Austenitise, Quench, Double Temper)

Jayant Impex can offer VACUUM DEGASSING (VD) route Alloy Steel 1.2316 Round Bars, 1.2316 Alloy Steel Round Forged Bars, 1.2316 Double Temper Forged Rods, 1.2316 Black Round Bars, 1.2316 Aircraft Quench Bright Round Bars, 1.2316 Normalised Rolled Round Bars, 1.2316 Austenitise Peeled Round Bars, 1.2316 Proof Machined Round Bars, 1.2316 Threaded Round Bars, 1.2316 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. Produced from Scrap Melting in form of Billet, Continuous Cast Billet, Bar, Rods, Round, Flat, Square, Round Corner Square(RCS), Straight Corner Square(SCS), Rectangular, Slabs, Blocks, Hexagonal, Hollow, Concast, Forged, Rolled, Black, Bright, Peeled, Proof Machined, Shafting (Shafts), Plate, Sheet, Coil, Circle, Strip, Foil, Ring (Seamless, Welded, Forged, Rolled), Tube, Tubing, Pipe, Flange, Fitting, Fastener, Stud or Threaded Rod, Bolt, Screw, Nut, Washer, Rivet, Circlip, Retaining Ring, Pin, Threaded Inserts, Standoffs, Spacers, Forgings, Machined Part, Welded Compenents, Welding Consumables, Filler Metal Wire Rod, Shims (Shim-Sheets), Wires, Springs, Bearings, Valve, Gasket, Filter, Silencers, Hard Chrome Plated (HCPR) Rod/Shafting, Pre-Honing, Honed Pipe, etc. or Virgin Ferro Alloys.

Specifications for Round Bars: As per AISI, SAE, UNS, ASTM, JIS, SS, UNE, STAS, GOST, PN, NS, UNI, ISO, IS, ONORM, NBN, CSA, GB, CSN, BS, EU, EN, SFS, AFNOR NF, DIN, WNr, NP, CSN

Size Range for 1.2316 Round Bars: 6mm upto 1200mm

Length for 1.2316 Round Bars: 10mm upto 6000mm depending on material grade & size.

Type of 1.2316 Round Bars: Hot Forged & Cold Forged.

Heat Treatment for Round Bars: Hot Rolled, Cold Drawn, Solution Annealed, Oil & Water Quenched / Tempered

Surface Finish for 1.2316 Round Bars: Bright & Black

1.2316 Round Bars End Finish: SHEARED / BANSAW CUT / HOT- CUT WITH GRINDING/ Water Jet Cutting.

From Jayant Impex Pvt Ltd, India, Maharashtra, Khopoli, Mumbai client can avail VACUUM DEGASSING (VD) route Alloy Steel 1.2316 Round Bars, 1.2316 Round Forged Bars, 1.2316 Double Temper Forged Rods, 1.2316 Black Round Bars, 1.2316 Aircraft Quench Bright Round Bars, 1.2316 Normalised Rolled Round Bars, 1.2316 Austenitise Peeled Round Bars, 1.2316 Proof Machined Round Bars, 1.2316 Threaded Round Bars, 1.2316 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc.

Client can procure smaller quantities of Alloy Steel 1.2316 Round Bars online ready stock from us at premium cost in any destination by just sending us an email.

If any requirements for Alloy Steel 1.2316 Round Bars, 1.2316 Alloy Steel Round Forged Bars, 1.2316 Double Temper Forged Rods, 1.2316 Black Round Bars, 1.2316 Aircraft Quench Bright Round Bars, 1.2316 Normalised Rolled Round Bars, 1.2316 Austenitise Peeled Round Bars, 1.2316 Proof Machined Round Bars, 1.2316 Threaded Round Bars, 1.2316 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. kindly do contact us.

Superior Corrosion Resistance

1.2316 tool steel stands out due to its exceptional resistance to corrosion, particularly in wet or humid environments. This makes it a preferred choice for mold cavities and inserts, where maintaining dimensional accuracy and a clean surface is crucial over prolonged use. Its chromium-rich composition is fundamental to its performance in demanding conditions.

Applications Across Industries

Extensively used in mold-making, 1.2316 tool steel also serves industries such as automotive and general manufacturing. With its ability to produce high-quality finishes, it is ideal for precision components. The steel is distributed, fabricated, and supplied by a broad network of industry professionals in India to cater to diverse industrial requirements.

FAQs of Tool Steel : 1.2316 / X38CrMo16:

Q: How is Tool Steel 1.2316 / X38CrMo16 commonly processed for mold making?

A: Tool Steel 1.2316 is typically processed through machining, heat treatment, and polishing. The steel can be precisely cut and shaped, hardened to required levels, and finished to achieve smooth surfaces, ensuring its suitability for mold cavities, cores, and inserts.Q: What are the main benefits of using 1.2316 tool steel in industrial applications?

A: The main benefits of 1.2316 tool steel include its outstanding corrosion resistance, ability to attain high hardness, and exceptional polishability. These characteristics lead to longer-lasting molds with minimal maintenance, improved product quality, and increased lifecycle.Q: Where can Tool Steel 1.2316 be sourced in India?

A: In India, Tool Steel 1.2316 is available through authorized dealers, distributors, exporters, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers. Its widespread availability ensures easy sourcing for various industrial projects.Q: When is it recommended to use 1.2316 over other tool steels?

A: 1.2316 is recommended when high corrosion resistance and a superior mirror finish are requiredparticularly in mold making for plastic injection, automotive parts, and components exposed to humid conditions. Its performance excels where conventional tool steels may be less effective.Q: What applications are best suited for Tool Steel 1.2316?

A: 1.2316 tool steel is best suited for manufacturing molds, cores, inserts, and die sets, especially those used in the plastic, automotive, and industrial sectors. Its properties make it ideal for precision components demanding durability and resistance to corrosion.Q: How does the usage of 1.2316 steel enhance productivity in manufacturing?

A: Using 1.2316 tool steel enhances productivity by reducing downtime due to its durability and resistance to wear and corrosion. This means longer service intervals between maintenance, leading to higher factory throughput and consistent product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free