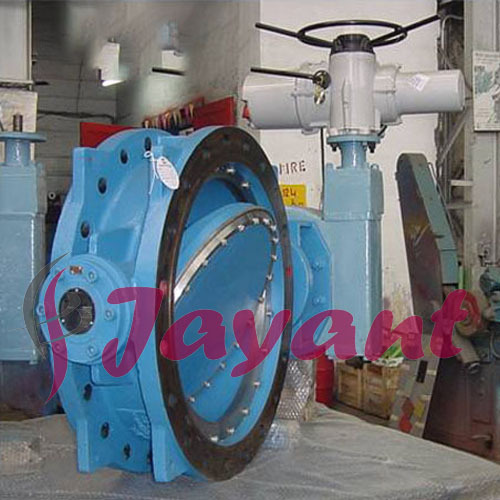

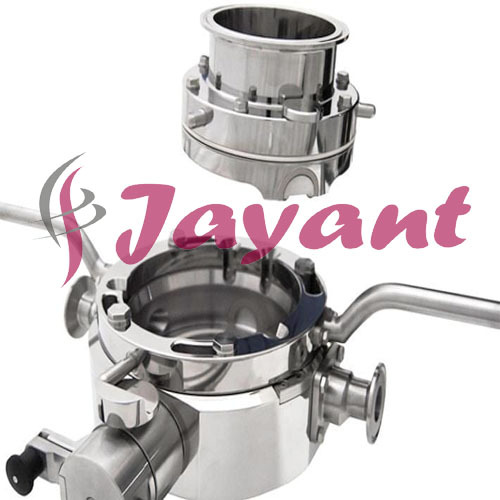

Stainless Steel Butterfly Valve

Product Details:

- Usage chemical, beverage, brewing, pharmacy, petroleum refining, ultrapure water, paper, mining, nuclear power, irrigation and other industries

- Valve Type Wafer Type Butterfly Valve

- Size 50mm to 600mm

- Material Stainless Steel

- Product Type Stainless Steel Butterfly Valve

- Click to view more

X

Stainless Steel Butterfly Valve Price And Quantity

- 1 Number

Stainless Steel Butterfly Valve Product Specifications

- Stainless Steel Butterfly Valve

- Stainless Steel

- chemical, beverage, brewing, pharmacy, petroleum refining, ultrapure water, paper, mining, nuclear power, irrigation and other industries

- 50mm to 600mm

- Wafer Type Butterfly Valve

Stainless Steel Butterfly Valve Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 52 Number Per Week

- 3 Week

- Western Europe, Central America, Australia, North America, South America, Eastern Europe, Middle East, Africa, Asia

- All India

Product Description

A stainless butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway.Robust Stainless Steel Construction

Built using premium stainless steel materials, this butterfly valve offers outstanding corrosion resistance, making it ideal for both aggressive and ultrapure applications. The robust body ensures a long service life and reliable functionality, even in challenging industrial environments where chemical exposure, moisture, or high temperatures are present. This durability reduces replacement frequency and overall maintenance costs.

Versatile Size Range and Applications

Available in sizes ranging from 50mm to 600mm, this wafer-type butterfly valve can be precisely matched to your piping requirements. The design is suitable for a vast selection of industries, including water treatment, food & beverage, pharmaceuticals, petroleum refining, mining, nuclear power, and more. Its adaptability ensures consistent, efficient flow control in numerous systems and processes.

FAQs of Stainless Steel Butterfly Valve:

Q: How is a stainless steel wafer type butterfly valve installed?

A: Wafer type butterfly valves are typically installed between two pipeline flanges. The valves slim profile fits snugly and is secured with bolts that pass through the flanges and valve body. The stainless steel construction ensures a firm seal, minimizing leaks and ensuring lasting performance.Q: What are the primary benefits of using stainless steel butterfly valves in industrial applications?

A: Stainless steel butterfly valves offer excellent corrosion resistance, high durability, and minimal maintenance requirements. These qualities make them suitable for harsh environments in industries like chemical processing, pharmaceuticals, and ultrapure water systems, ultimately ensuring safe and reliable flow control.Q: When should I choose a butterfly valve over other valve types?

A: Butterfly valves are ideal when you require quick shut-off, tight sealing, and the ability to handle large flow volumes with relatively low pressure drops. Their straightforward operation and compact design make them preferable in pipelines where space is limited or frequent operation is necessary.Q: Where can I source stainless steel butterfly valves in India?

A: These valves are widely available from authorized dealers, distributors, exporters, manufacturers, suppliers, and wholesalers throughout India. Many providers offer custom configurations and prompt delivery to match specific industrial requirements.Q: What industries commonly use stainless steel butterfly valves of sizes 50mm to 600mm?

A: Industries such as chemical, beverage, brewing, pharmacy, petroleum refining, paper, mining, nuclear power, irrigation, and ultrapure water utilize these valves due to their robust construction and adaptability to various media and operating conditions.Q: What is the process for maintaining a stainless steel butterfly valve?

A: Routine maintenance involves periodic inspection for seat wear, checking for leaks, and ensuring smooth operation of the disc and handle. Stainless steel construction minimizes corrosion, and regular cleaning keeps the valve in peak working order, making maintenance straightforward and cost-effective.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free