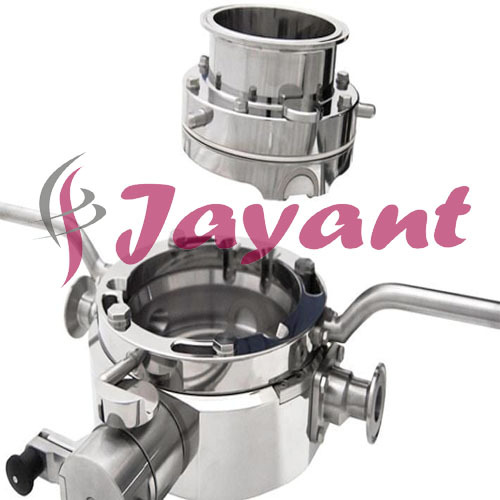

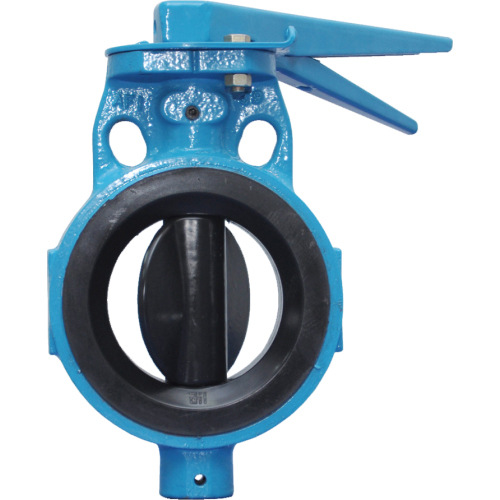

Split Butterfly Valve

65000 INR/Number

Product Details:

- Material Carbon Steel, Stainless Steel, Rubber, Plastic, Casting, Alloy, Brass, Forged, PVC, UPVC, PP-R, Aluminum, Ceramic, Wood, Ductile Iron

- Size 50mm to 900mm

- Product Type Split Butterfly Valve

- Pressure High Pressure

- Media Oil

- Working Temperature Medium

- Color ANY COLOUR

- Click to view more

X

Split Butterfly Valve Price And Quantity

- 1 Number

- 65000 INR/Number

- 65000.00 - 250000.00 INR/Number

Split Butterfly Valve Product Specifications

- 50mm to 900mm

- Carbon Steel, Stainless Steel, Rubber, Plastic, Casting, Alloy, Brass, Forged, PVC, UPVC, PP-R, Aluminum, Ceramic, Wood, Ductile Iron

- Medium

- Oil

- High Pressure

- Split Butterfly Valve

- ANY COLOUR

Split Butterfly Valve Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 52 Number Per Week

- 3 Week

- Western Europe, Central America, South America, Middle East, Eastern Europe, Asia, North America, Australia, Africa

- All India

Product Description

Split Butterfly Valve (SBV) Split Butterfly Valves (SBVs), or containment valve, technology provides a safe method of transferring product from one container or process vessel to another whilst minimising the levels of dust emission to the operating environment before, during and after the material transfer.Versatile Material Options

Choose from more than a dozen material types, including carbon steel, stainless steel, plastics, ceramics, and aluminum, ensuring compatibility with various industrial needs and oil media. This broad material selection supports diverse operating environments and pressure requirements.

Wide Size Range for All Applications

The valve is available in diameters from 50mm to 900mm, catering to both small-scale and large-capacity installations. Its size flexibility makes it ideal for custom process systems and high-volume operations.

Reliable for High Pressure Environments

Engineered for high pressure, the split butterfly valve maintains performance integrity and safety when handling demanding oil transmission processes. This ensures stable operation and long service life in rigorous industrial settings across India.

FAQs of Split Butterfly Valve:

Q: How are split butterfly valves installed in oil processing systems?

A: Split butterfly valves are typically installed between pipe flanges. The process involves aligning the valve, securing it with bolts, and connecting it to an appropriate actuator or handle. Detailed installation guides are provided by manufacturers and suppliers to suit the specific material and pressure requirements.Q: What materials are best suited for high pressure applications in split butterfly valves?

A: For high pressure oil applications, materials like carbon steel, stainless steel, forged alloys, and ductile iron are highly recommended. These provide strength, longevity, and resistance to leakage or deformation under pressure.Q: When should a split butterfly valve be used instead of traditional valves?

A: Split butterfly valves are best used when a compact, lightweight valve is needed for frequent operation, especially in high-pressure oil media. They are preferred for their fast open/close action, reduced maintenance needs, and compatibility with a wide selection of piping materials.Q: Where can I source split butterfly valves with custom specifications in India?

A: In India, split butterfly valves can be sourced from a broad network of dealers, distributors, manufacturers, and suppliers. Many exporters and retailers also provide custom specification options concerning size, material, color, and end-use applications.Q: What is the typical process for selecting the right split butterfly valve for my system?

A: The selection process involves assessing media type, pressure rating, temperature, required materials, and size. Consultation with fabricators or manufacturers ensures that you choose a valve compatible with your oil systems pressure and chemical requirements.Q: How does using a split butterfly valve benefit my operation?

A: Utilizing a split butterfly valve offers benefits such as swift and reliable flow control, minimal maintenance, and adaptability to various piping systems. Their high-pressure resilience and broad material range also contribute to operational safety and longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free