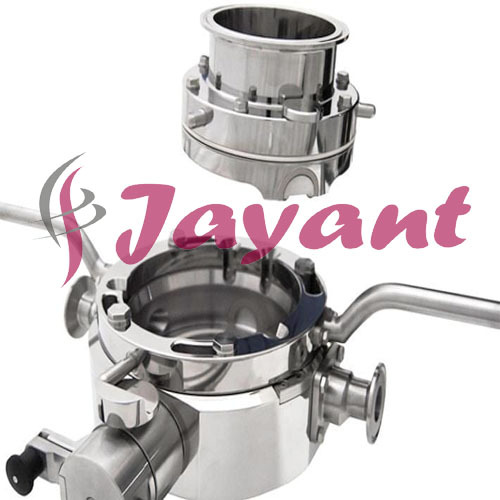

Lined butterfly valve

Product Details:

- Connection Thread

- Usage water, brine, pulp stock and weak acid applications

- Material Carbon Steel, Rubber, Stainless Steel, Plastic, Casting, Alloy, Brass, Forged, PVC, UPVC, Wood, PP-R, Aluminum, Ceramic, Ductile Iron

- Size 50mm to 900mm

- Product Type Lined butterfly valve

- Media Base

- Working Temperature Medium

- Click to view more

X

Lined butterfly valve Price And Quantity

- 1 Number

Lined butterfly valve Product Specifications

- 50mm to 900mm

- Medium

- Thread

- Carbon Steel, Rubber, Stainless Steel, Plastic, Casting, Alloy, Brass, Forged, PVC, UPVC, Wood, PP-R, Aluminum, Ceramic, Ductile Iron

- Lined butterfly valve

- water, brine, pulp stock and weak acid applications

- Base

- Blue

Lined butterfly valve Trade Information

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Week

- 3 Week

- Australia, Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- All India

Product Description

PFA / PTFE lined butterfly valve is designed for control and the isolation of aggressive media. A fully Lined valve is highly recommended for abrasive and corrosive applications where require reliable performance, drop-tight shutoff, constant torque and no maintenance.Versatile Flow Control Solution

Our lined butterfly valves are designed to handle a variety of mediaincluding water, brine, pulp stock, and weak acidsmaking them ideal for industries such as chemical processing, pulp and paper, water treatment, and more. With sizes ranging from 50mm to 900mm, these valves offer precise control for small and large-scale requirements alike.

Robust Materials for Durability

Built using high-quality materials like carbon steel, stainless steel, alloys, various plastics, and ceramics, these butterfly valves ensure prolonged service life and resistance to corrosion and wear. The choice of materials is tailored to suit medium-temperature applications and diverse operating environments.

Wide Distribution Network Across India

We operate as manufacturers, suppliers, exporters, traders, fabricators, and wholesalers of lined butterfly valves throughout India. With a strong logistics framework, we efficiently cater to the needs of dealers and end-users nationwide, offering prompt deliveries and comprehensive technical support.

FAQs of Lined butterfly valve:

Q: How are lined butterfly valves typically installed in water and chemical applications?

A: Installation of lined butterfly valves in water, brine, pulp stock, or weak acid applications is straightforward due to their threaded connections, which allow secure and leak-proof assembly. Ensure compatibility of the line pressure and medium with the valve materials and follow recommended torque specifications during installation.Q: What benefits do lined butterfly valves offer over other types of valves in industrial systems?

A: Lined butterfly valves are lightweight, cost-effective, and offer efficient flow control with minimal pressure drop. Their specialized lining materials provide excellent chemical resistance, reducing the risk of corrosion and maintenance requirements in aggressive environments.Q: When should lined butterfly valves be chosen for a process system?

A: Choose lined butterfly valves when handling corrosive or abrasive media such as weak acids, brine, or pulp stock. They are ideal for medium-temperature operations and applications where reliability, chemical resistance, and easy maintenance are essential.Q: Where can I purchase lined butterfly valves in sizes up to 900mm across India?

A: Lined butterfly valves from 50mm to 900mm are available from our expansive network of dealers, distributors, manufacturers, suppliers, and traders throughout India. We ensure nationwide coverage and support for diverse industrial requirements.Q: What is the manufacturing process for lined butterfly valves?

A: The manufacturing process involves precision casting or forging of the body, followed by machining. Linings such as rubber, plastic, or alloys are then applied based on application requirements, with rigorous quality checks to ensure leak-proof and durable performance.Q: How should lined butterfly valves be used for optimal performance?

A: For best results, operate the valves within their specified pressure and temperature ranges. Regular inspections and proper installation help maintain sealing integrity and long-term reliability, especially in demanding fluids like brine or weak acids.Q: What are the primary advantages of using lined butterfly valves in corrosive environments?

A: Lined butterfly valves provide superior resistance to corrosion and wear, ensuring long service life, minimal maintenance, and reliable shutoff performance even when exposed to aggressive chemicals and fluctuating process conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free