Inconel 718 per AMS 5663

Product Details:

- Material Inconel 718 per AMS 5663

- Diameter 0.750 to 3.000 Millimeter (mm)

- Standard AMS

- Application Aerospace, Jet Engines, MWD/LWD Tools, Fasteners, Spring, Pump Parts, Shafts, etc.

- Click to view more

Inconel 718 per AMS 5663 Price And Quantity

- 500.00 - 5000.00 INR/Number

- 1 Number

- 5000 INR/Number

Inconel 718 per AMS 5663 Product Specifications

- 0.750 to 3.000 Millimeter (mm)

- AMS

- Aerospace, Jet Engines, MWD/LWD Tools, Fasteners, Spring, Pump Parts, Shafts, etc.

- Inconel 718 per AMS 5663

Inconel 718 per AMS 5663 Trade Information

- Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID), Cheque

- Yes

- Contact us for information regarding our sample policy

- Australia, Central America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, North America

- All India

Product Description

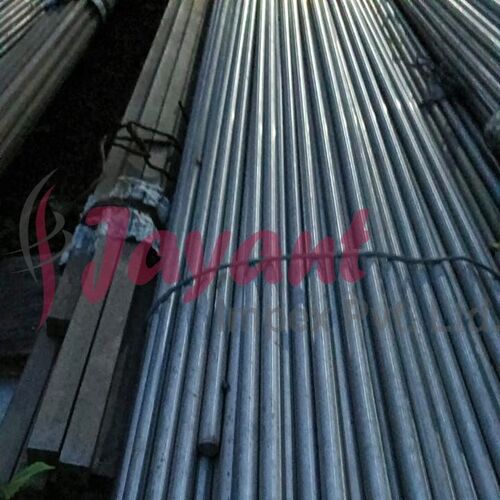

Jayant Impex trades Inconel 718 per AMS 5663 in the form of round bar, flat bar, rod, pipe, tube, cast/forged parts, sheets, plates, flanges, etc or can provide it as per clients requirement.

From Jayant Impex Pvt Ltd, India, Maharashtra, Khopoli, Mumbai client can avail VACUUM DEGASSING (VD) route Alloy Steel Inconel 718 per AMS 5663 Round Bars, Inconel 718 per AMS 5663 Round Forged Bars, Inconel 718 per AMS 5663 Double Temper Forged Rods, Inconel 718 per AMS 5663 Black Round Bars, Inconel 718 per AMS 5663 Aircraft Quench Bright Round Bars, Inconel 718 per AMS 5663 Normalised Rolled Round Bars, Inconel 718 per AMS 5663 Austenitise Peeled Round Bars, Inconel 718 per AMS 5663 Proof Machined Round Bars, Inconel 718 per AMS 5663 Threaded Round Bars, Inconel 718 per AMS 5663 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc.

Client can procure smaller quantities of Alloy Steel Inconel 718 per AMS 5663 Round Bars online ready stock from us at premium cost in any destination by just sending us an email.

If any requirements for Alloy Steel Inconel 718 per AMS 5663 Round Bars, Inconel 718 per AMS 5663 Alloy Steel Round Forged Bars, Inconel 718 per AMS 5663 Double Temper Forged Rods, Inconel 718 per AMS 5663 Black Round Bars, Inconel 718 per AMS 5663 Aircraft Quench Bright Round Bars, Inconel 718 per AMS 5663 Normalised Rolled Round Bars, Inconel 718 per AMS 5663 Austenitise Peeled Round Bars, Inconel 718 per AMS 5663 Proof Machined Round Bars, Inconel 718 per AMS 5663 Threaded Round Bars, Inconel 718 per AMS 5663 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. kindly do contact us.

Outstanding High-Temperature Performance

Inconel 718 per AMS 5663 excels in high-stress, high-heat environments. Its resilience against oxidation and superior mechanical properties ensure reliability for components used in jet engines and demanding aerospace applications. This makes it a preferred choice for manufacturers looking for both performance and dependability.

Broad Industrial Applicability

Due to its strength, ductility, and corrosion resistance, Inconel 718 finds use in a multitude of critical sectors. From high-precision aerospace parts to robust oil & gas drilling tools, and durable fasteners or springs, it addresses complex engineering challenges while offering sustained functional integrity.

FAQs of Inconel 718 per AMS 5663:

Q: How is Inconel 718 per AMS 5663 typically processed for use in aerospace applications?

A: Inconel 718 is processed using advanced melting, forging, and precipitation hardening heat treatments to achieve the high mechanical strengths required by AMS 5663. This ensures the material meets strict industry specifications for aerospace and jet engine components.Q: What advantages does Inconel 718 per AMS 5663 provide over other superalloys?

A: Compared to many other superalloys, Inconel 718 exhibits superior tensile, fatigue, and creep-rupture strength at high temperatures, along with remarkable resistance to corrosion and oxidation. These benefits make it ideal for applications where component reliability is essential.Q: When should Inconel 718 per AMS 5663 be considered in product design?

A: This alloy should be considered when designing parts exposed to high temperatures, aggressive chemical environments, or requiring exceptional strength such as in jet engines, MWD/LWD drilling tools, pumps, and fasteners.Q: Where can I source Inconel 718 per AMS 5663 in India?

A: Inconel 718 per AMS 5663 is widely available through dealers, distributors, exporters, manufacturers, suppliers, and wholesalers across India, especially in major industrial hubs.Q: What is the typical diameter range supplied for Inconel 718 per AMS 5663?

A: The standard supply range is 0.750 to 3.000 millimeters in diameter, suitable for precision components used in aerospace and related industries.Q: How does the process of heat treatment benefit Inconel 718 per AMS 5663 components?

A: Heat treatment enhances the precipitation-hardened microstructure of Inconel 718, significantly improving its mechanical strength, durability, and resistance to stress-related failures common in high-temperature service conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free