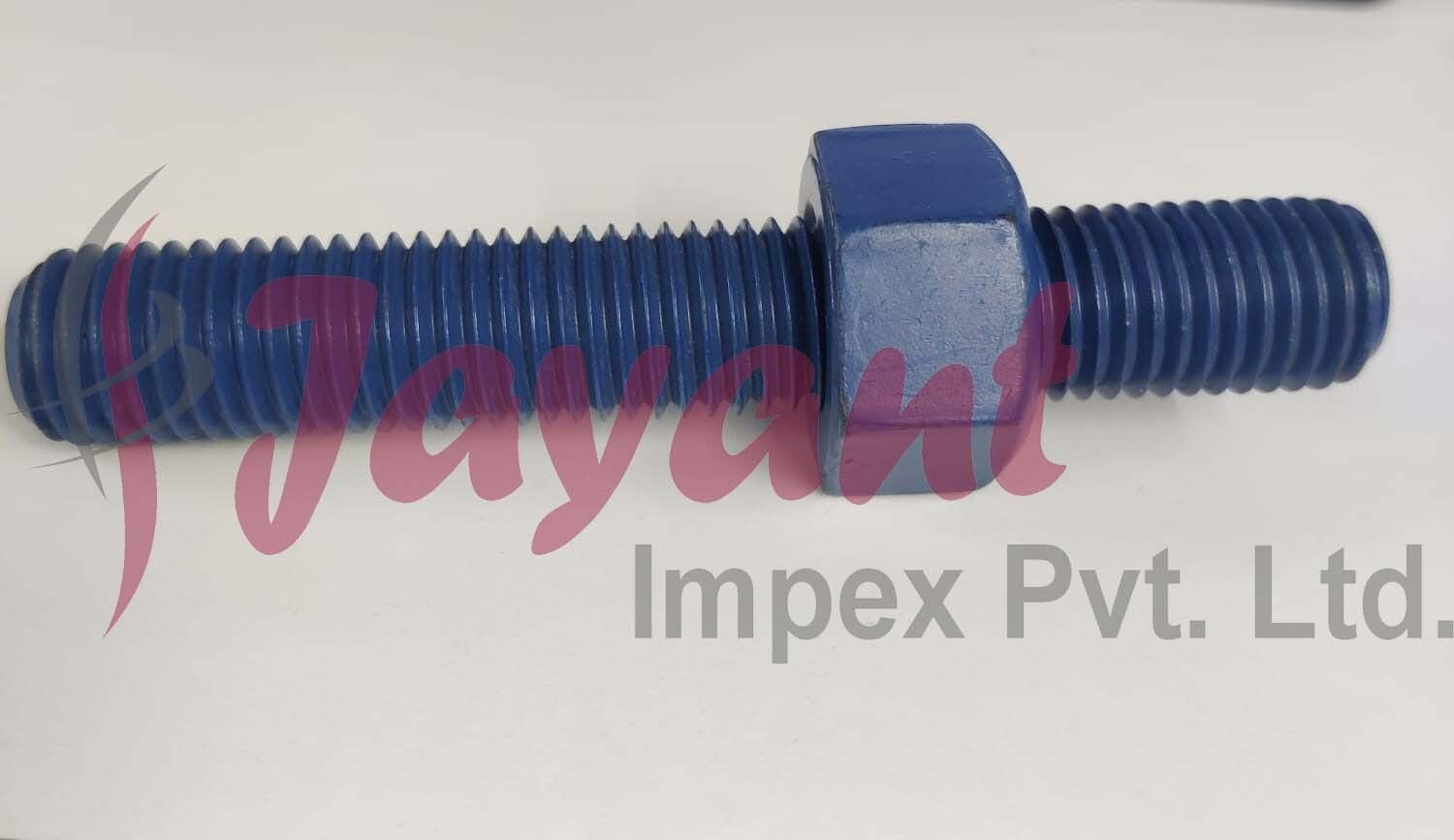

PTFE Coated Fasteners

Product Details:

- Usage Industrial, Engineering, Food Industry, Chemical Industry, Offshore Industry, Oil and Gas Industry, Pharmaceutical, Deep Sea Drilling, Marine Industry, Nuclear Industry

- Product Type PTFE Coated Fasteners

- Click to view more

PTFE Coated Fasteners Price And Quantity

- 1 Number

- 5000 INR/Number

- 500.00 - 5000.00 INR/Number

PTFE Coated Fasteners Product Specifications

- PTFE Coated Fasteners

- Industrial, Engineering, Food Industry, Chemical Industry, Offshore Industry, Oil and Gas Industry, Pharmaceutical, Deep Sea Drilling, Marine Industry, Nuclear Industry

PTFE Coated Fasteners Trade Information

- Cheque, Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 7 Days

- Yes

- Asia, Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, North America, Africa

- All India

Product Description

Jayant Impex is importing, trading, wholesaling, buying, supplying fasteners purchased from various countries worldwide including USA, Canada, Europe, Spain, United Kingdom, Germany, Far East, India, UAE, Saudi Arabia (KSA), New Orleans, Houston, Texas, Korea, Asia, Italy, France, Singapore, Malaysia, Doha, Qatar, Thailand, Australia, etc.

We can offer very competitive prices for this which are produced from Billet, Continuous Cast Billet, Bar, Rods, Round, Flat, Square, Round Corner Square(RCS), Straight Corner Square(SCS), Rectangular, Slabs, Blocks, Hexagonal, Hollow, Concast, Forged, Rolled, Black, Bright, Peeled, Proof Machined, Shafting (Shafts), Plate, Sheet, Coil, Circle, Strip, Foil, Ring (Seamless, Welded, Forged, Rolled), Tube, Tubing, Pipe, Flange, Fitting, Fastener, Stud or Threaded Rod, Bolt, Screw, Nut, Washer, Rivet, Circlip, Retaining Ring, Pin, Threaded Inserts, Standoffs, Spacers, Forgings, Machined Part, Welded Compenents, Welding Consumables, Filler Metal Wire Rod, Shims (Shim-Sheets), Wires, Springs, Bearings, Valve, Gasket, Filter, Silencers, Hard Chrome Plated (HCPR) Rod/Shafting, Pre-Honing, Honed Pipe, etc. or Virgin Ferro Alloys.

Exceptional Corrosion Resistance

PTFE coated fasteners provide outstanding protection against corrosive agents, making them ideal for chemical processing, offshore, and marine applications. This robust coating helps extend the lifespan of fasteners, particularly in environments where exposure to saltwater, aggressive chemicals, or high moisture is routine.

Industries Served Across India

These fasteners are trusted by leading sectors in India, including engineering, food, pharmaceutical, oil & gas, nuclear, and deep-sea drilling. Their adaptability and reliability make them popular with manufacturers, exporters, suppliers, and traders for numerous challenging projects.

FAQs of PTFE Coated Fasteners:

Q: How are PTFE coated fasteners beneficial for the food and pharmaceutical industries?

A: PTFE coated fasteners are chemically inert and possess non-stick properties, which make them suitable for hygienic applications in the food and pharmaceutical industries. The coating resists bacteria build-up and simplifies cleaning, ensuring compliance with strict industry standards.Q: What is the main process used to apply PTFE coatings to fasteners?

A: PTFE coatings are typically applied through a controlled spraying or dipping process followed by curing at elevated temperatures. This ensures an even, durable, and highly adherent layer that enhances the fasteners performance under extreme conditions.Q: When should PTFE coated fasteners be used in engineering and industrial contexts?

A: These fasteners are recommended whenever there is a need for resistance to corrosion, high temperatures, aggressive chemicals, or in situations requiring reduced friction and maintenance. They are especially valuable for long-term reliability in harsh operational environments.Q: Where are PTFE coated fasteners commonly supplied and distributed in India?

A: PTFE coated fasteners are widely available throughout India via an extensive network of manufacturers, distributors, exporters, retailers, suppliers, and wholesalers, ensuring convenient access for various sectors and projects nationwide.Q: What are the main benefits of using PTFE coated fasteners in offshore and deep-sea drilling operations?

A: In offshore and deep-sea drilling, PTFE coated fasteners provide superior resistance to saltwater corrosion and prevent seizing under high pressure. Their durability helps reduce maintenance frequency and enhances safety during demanding operations.Q: How do PTFE coated fasteners enhance performance in the chemical and nuclear industries?

A: These fasteners offer outstanding resistance to most chemicals, acids, and solvents, protecting structural integrity even when exposed to hazardous or radioactive environments. Their reliability under extreme conditions is critical in these highly regulated industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free