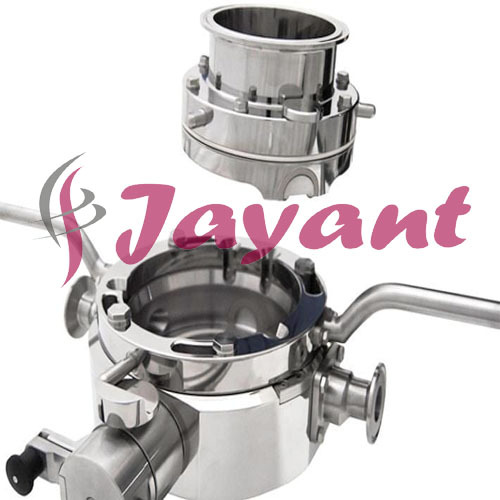

Double flanged butterfly valves

Product Details:

- Valve Type Wafer Type Butterfly Valve

- Size DN50 to DN2800.

- Material Carbon Steel, Stainless Steel, Plastic, Casting, Alloy, Brass, Forged, Rubber, PVC, UPVC, Wood, PP-R, Aluminum, Ceramic, Ductile Iron

- Product Type Double flanged butterfly valves

- Media Gas

- Working Temperature Medium

- Color ANY COLOUR

- Click to view more

X

Double flanged butterfly valves Price And Quantity

- 1 Number

Double flanged butterfly valves Product Specifications

- Wafer Type Butterfly Valve

- Gas

- ANY COLOUR

- Medium

- Carbon Steel, Stainless Steel, Plastic, Casting, Alloy, Brass, Forged, Rubber, PVC, UPVC, Wood, PP-R, Aluminum, Ceramic, Ductile Iron

- Double flanged butterfly valves

- DN50 to DN2800.

Double flanged butterfly valves Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 50 Number Per Week

- 3 Week

- Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Australia, Africa

- All India

Product Description

Double flange butterfly valve used for regulation and flow sectioning in water supply facilities, plumbing, irrigation, etc. It has low head loss due to a hydrodynamic design of the disc, it is 100% water tight and need no gaskets to be installed.Wide Material Compatibility

Select from an extensive variety of materialscarbon steel, stainless steel, plastics, alloy, ceramic, rubber, and moretailored to your projects requirements. Our double flanged butterfly valves ensure compatibility and durability, making them suitable for diverse industries and applications.

Flexible Sizing and Customization

With sizes ranging from DN50 up to DN2800, these valves accommodate both small- and large-scale gas flow operations. Customization in colour and material allows for seamless integration with your existing pipeline systems and branding requirements.

FAQs of Double flanged butterfly valves:

Q: How are double flanged butterfly valves installed in gas pipelines?

A: Double flanged butterfly valves are usually mounted between pipeline flanges using bolts. Their wafer type design allows for easy alignment and secure fitting, streamlining installation in both new and existing gas pipeline systems.Q: What materials are available for these butterfly valves, and how do I select the right one?

A: They are crafted in a wide selection of materials, including carbon steel, stainless steel, brass, alloy, ceramics, ductile iron, PVC, and more. The suitable material depends on your applications media, temperature, and environmental requirements, ensuring optimal valve longevity and safety.Q: When is it beneficial to use a wafer type butterfly valve over other types?

A: Wafer type butterfly valves are beneficial when space is limited, weight should be minimized, and cost efficiency is desired. They offer quick operation and are ideal for gas media at medium temperatures, making them suitable for many industrial environments.Q: Where do you supply and export your double flanged butterfly valves?

A: We supply and export our valves across India and globally. Our extensive distribution network includes dealers, distributors, manufacturers, retailers, traders, and wholesalers, ensuring prompt availability wherever your project is located.Q: What is the manufacturing process for these valves?

A: The process begins with selecting the appropriate raw material, followed by precision casting or forging, machining, assembling valve components, applying surface treatments, and conducting rigorous quality tests to ensure each valve meets industry standards.Q: How can businesses benefit from using your double flanged butterfly valves?

A: Our valves provide long-term reliability, easy maintenance, and efficient flow control. The versatile material and size options allow businesses to tailor solutions to their exact needs, improving system performance and reducing operational downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free