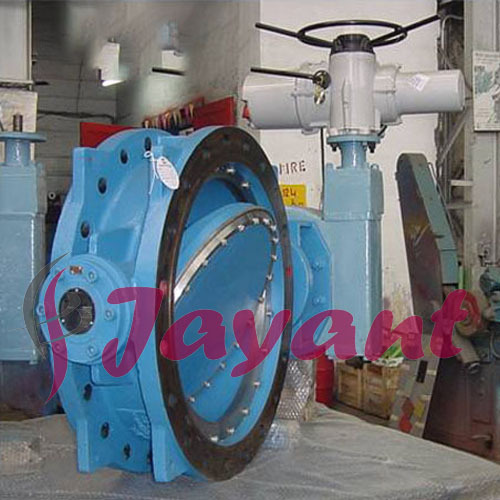

Wafer Butterfly Valve

Product Details:

- Valve Type Wafer Type Butterfly Valve

- Size 50mm to 600mm

- Material Carbon Steel, Stainless Steel, Brass, Plastic, Casting, Alloy, Forged, Rubber, PVC, UPVC, Wood, PP-R, Ceramic, Aluminum, Ductile Iron

- Product Type Wafer Butterfly Valve

- Color Blue

- Click to view more

X

Wafer Butterfly Valve Price And Quantity

- 1 Number

Wafer Butterfly Valve Product Specifications

- Wafer Type Butterfly Valve

- 50mm to 600mm

- Carbon Steel, Stainless Steel, Brass, Plastic, Casting, Alloy, Forged, Rubber, PVC, UPVC, Wood, PP-R, Ceramic, Aluminum, Ductile Iron

- Blue

- Wafer Butterfly Valve

Wafer Butterfly Valve Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Month

- 4 Week

- Central America, Australia, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- All India

Product Description

Most wafer-style butterfly valves are engineered with four holes that align with the connected pipeline. The valve is designed to clamp between two flanges in your pipe work. Most wafer butterfly valves fit the majority of flange standardsLugged butterfly valves have a round disc with lugs that attach the disc to the valve's body. Wafer butterfly valves have a disc attached to the valve's body with screws or bolts. Both types of butterfly valves are used to control the flow of liquids and gases

Versatile Material Options

Engineered from a variety of materials such as stainless steel, PVC, aluminum, and ceramic, the wafer butterfly valve offers tailored solutions for different environments and fluids. The range encompasses corrosion resistance, strength, and adaptability, making these valves suitable for water treatment, chemical processing, and HVAC applications.

Wide Sizing Range for Multiple Applications

With sizes available from 50mm up to 600mm, these valves accommodate a broad spectrum of pipeline diameters. Whether for compact plumbing systems or large industrial setups, this flexibility ensures optimal flow control and reduced pressure drop across the valve.

FAQs of Wafer Butterfly Valve:

Q: How is a wafer butterfly valve installed in a pipeline?

A: A wafer butterfly valve is positioned between two pipe flanges. It is then secured using bolts that pass through the flanges and the valve body, creating a tight, reliable seal suitable for diverse applications.Q: What materials are available for wafer butterfly valves, and how do they affect usage?

A: These valves are manufactured from materials such as carbon steel, stainless steel, brass, plastic, alloy, rubber, PVC, and more. The choice of material depends on the specific fluid, pressure, and temperature requirements, ensuring optimal performance and corrosion resistance.Q: Where can I buy wafer butterfly valves in India?

A: Wafer butterfly valves are available through a wide network of dealers, distributors, manufacturers, and retailers across India. Major cities and industrial hubs typically offer several options for sourcing these valves.Q: When should a wafer butterfly valve be chosen over other valve types?

A: Wafer butterfly valves are best suited for situations requiring quick shutoff, flow modulation, or minimization of space and weight. Their slim design and ease of installation make them preferable in pipelines with limited room.Q: What is the general process for fabricating wafer butterfly valves?

A: Fabrication involves selecting suitable materials, molding or forging the valve body, machining the sealing surfaces, assembling the disc and seat, and finishing with a blue coating for identification. Each valve type is quality-tested before market release.Q: How does the use of different materials benefit the operation of a wafer butterfly valve?

A: Using various materials like stainless steel for corrosion resistance or rubber for flexible sealing enables these valves to safely handle a wide range of fluids, temperatures, and pressures, enhancing reliability and longevity in service.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free