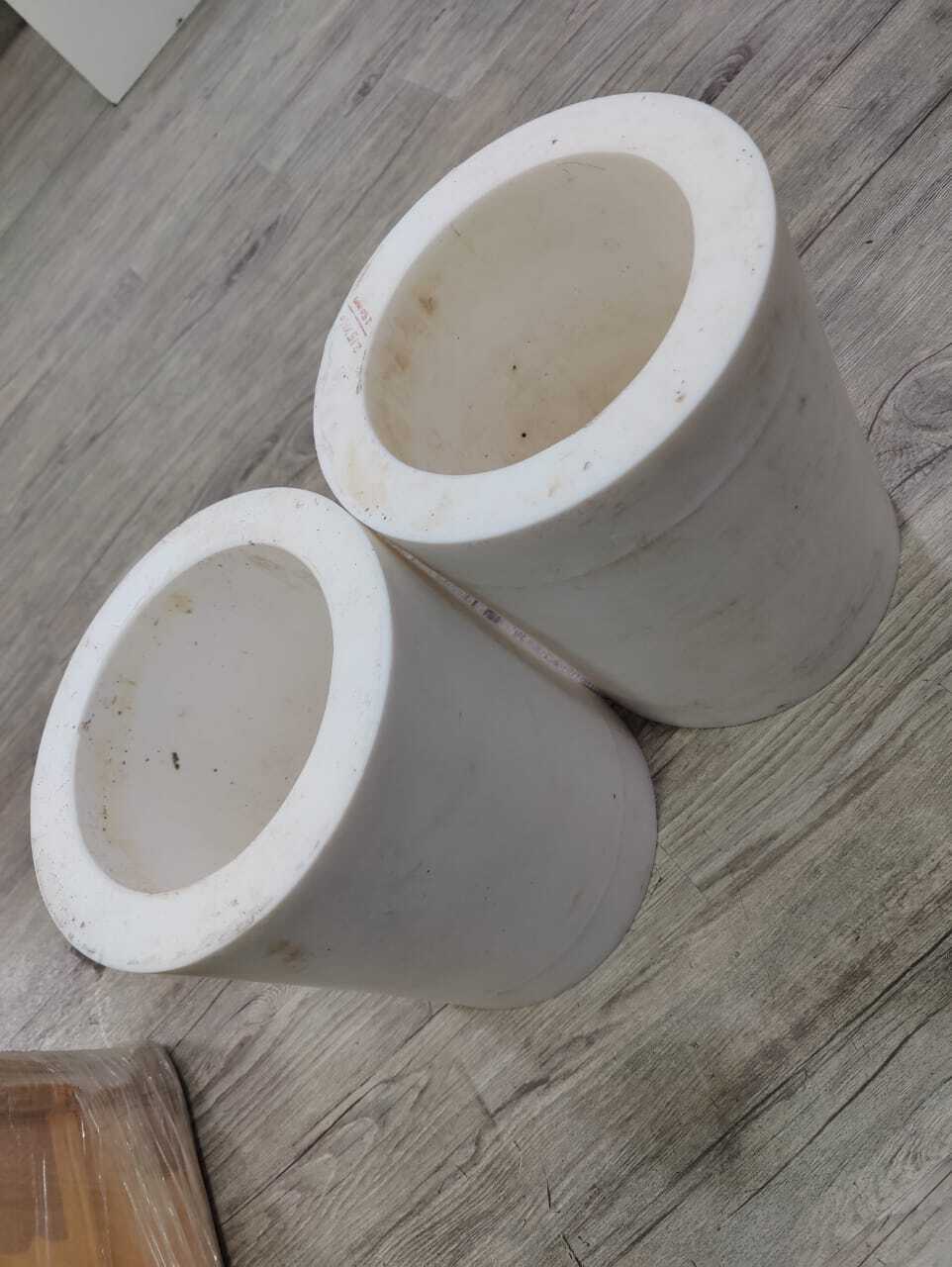

Virigin PTFE Bushes

2000 INR/Number

Product Details:

- Length 1000 Meter (m)

- Application PTFE can be used on extrusion dies and sealing of plastic/elastomers where other treatments may degrade or cause clogging of molten material, bicycle chains, pans, baking trays, insulation of wires and cables, tubing, pipe liners and films, gaskets, valves, wire insulation, insulated transformers, bearings, surface coatings, chemical processing equipment, chemical transport and PTFE rubber diaphragms, Plain bearings, Slide plates, Seal rings, Food industry, Machine parts, Armor-piercing bullets, Electrets, Fabric and carpet industry,

- Type Virgin, Carbon Filled, Graphite filled, bronze filled

- Material PTFE Material

- Click to view more

X

Virigin PTFE Bushes Price And Quantity

- 1 Number

- 2000.00 - 20000.00 INR/Number

- 2000 INR/Number

Virigin PTFE Bushes Product Specifications

- Virgin, Carbon Filled, Graphite filled, bronze filled

- PTFE can be used on extrusion dies and sealing of plastic/elastomers where other treatments may degrade or cause clogging of molten material, bicycle chains, pans, baking trays, insulation of wires and cables, tubing, pipe liners and films, gaskets, valves, wire insulation, insulated transformers, bearings, surface coatings, chemical processing equipment, chemical transport and PTFE rubber diaphragms, Plain bearings, Slide plates, Seal rings, Food industry, Machine parts, Armor-piercing bullets, Electrets, Fabric and carpet industry

- 1000 Meter (m)

- PTFE Material

Virigin PTFE Bushes Trade Information

- Nhava Sheva

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- 1 Number Per Day

- 1 Week

- Yes

- Within a certain price range free samples are available

- Wooden Box packing, corrugated box packing, free ex-works

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- ISO

Product Description

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene. Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, though its perhaps best-known for its non-stick properties.Exceptional Material Qualities

Virgin PTFE Bushes stand out for their tremendous resistance to heat, chemicals, and wear. Their non-stick surface and high density make them ideally suited to both heavy-duty industrial and high-precision applications. The smooth finish ensures consistent performance with minimal maintenance requirements.

Versatile Industrial Applications

Due to their broad temperature tolerance and inert nature, these bushes are incorporated in areas such as extrusion die sealing, insulating wires, food processing machinery, and surface coatings. Their adaptability allows them to function reliably in sectors ranging from electrical insulation to chemical processing.

Reliable Sourcing Across India

Virgin PTFE Bushes are available through an extensive network of distributors, exporters, dealers, and manufacturers throughout India. This widespread availability ensures prompt procurement for a wide range of industrial projects, supporting both large-scale manufacturers and smaller enterprises.

FAQs of Virigin PTFE Bushes:

Q: How are Virgin PTFE Bushes typically installed in machinery?

A: Virgin PTFE Bushes are designed for easy installation, typically by sliding into the designated housing or component. Their precise dimensions and smooth surface finish allow a snug fit without the need for specialized tools, minimizing installation time and reducing maintenance requirements.Q: What benefits do Virgin PTFE Bushes offer compared to conventional bush materials?

A: These bushes provide several key advantages, including high durability, exceptional low friction, excellent chemical resistance, and superior heat resistance. The non-stick property of PTFE ensures that bushings remain clean and functional even under harsh conditions, resulting in longer service life and reduced downtime.Q: Where can Virgin PTFE Bushes be used in the food industry?

A: In the food industry, Virgin PTFE Bushes are commonly found in machines such as pans, baking trays, and sealing systems where hygiene and non-stick characteristics are crucial. Their ability to withstand high temperatures and resist chemical cleaning agents makes them ideal for food processing equipment.Q: When should I choose Virgin PTFE Bushes over filled PTFE variants?

A: Virgin PTFE Bushes are ideal when the highest possible purity, non-reactivity, and electrical insulating properties are required. For applications that demand additional strength or wear resistance, filled PTFE variants (such as carbon, graphite, or bronze-filled) may be more appropriate.Q: What processes are involved in manufacturing Virgin PTFE Bushes?

A: The production process typically includes extrusion or molding, followed by precision machining to achieve tight tolerances and a smooth surface finish. Strict quality checks ensure that each bush meets the demanding requirements for dimensional accuracy and material consistency.Q: How does the high chemical resistance of Virgin PTFE Bushes benefit industrial users?

A: Their outstanding chemical resistance makes them suitable for use in environments exposed to aggressive acids, bases, and solvents. This property prevents degradation, prolongs operational life, and enhances overall reliability in chemical processing, transport, and sealing applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free