Stainless Steel Check Valves

105000 INR/Number

Product Details:

- Power Pneumatic

- Size /8" TO 2" / 6 MM TO 50 MM

- Pressure Low Pressure

- Product Type Stainless Steel Check Valves

- Media Gas, Base, Water, Oil, Acid

- Click to view more

X

Stainless Steel Check Valves Price And Quantity

- 105000.00 - 110000.00 INR/Number

- 1 Number

- 105000 INR/Number

Stainless Steel Check Valves Product Specifications

- Pneumatic

- Low Pressure

- Stainless Steel Check Valves

- /8" TO 2" / 6 MM TO 50 MM

- Gas, Base, Water, Oil, Acid

Stainless Steel Check Valves Trade Information

- Nhava Sheva

- Cash Advance (CA), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 5 Number Per Week

- 5 Months

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

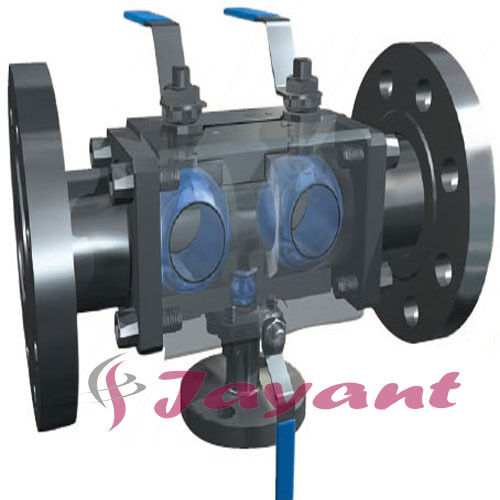

Check valves areone-way or nonreturn valves that open with fluid movement and pressure, and close to prevent backflow of the pressure to upstream equipment such as pumps and compressors. In fact, check valves allow the fluid to flow in only one direction.Versatility for Multiple Media

Designed to handle gases, water, oils, acids, and bases, our stainless steel check valves provide exceptional flexibility for a variety of low-pressure pneumatic systems. The robust construction ensures durability and performance across different industries, making them ideal for plants and process systems.

Precise Sizes for Varied Applications

Available in sizes from 1/8" to 2" (6 mm to 50 mm), our check valves can accommodate diverse piping systems. Built from high-grade stainless steel, they maintain peak performance even in challenging environments, whether for small-scale setups or larger industrial lines.

Quality Guaranteed by Trusted Suppliers

As a manufacturer, supplier, and distributor based in India, we adhere to rigorous quality standards. Our valves undergo strict testing before dispatch, ensuring reliable operation, minimal maintenance, and customer satisfaction, whether you are a retailer, fabricator, or wholesaler.

FAQs of Stainless Steel Check Valves:

Q: How do stainless steel check valves work in pneumatic low-pressure systems?

A: Stainless steel check valves operate by allowing fluid or gas to flow in only one direction, preventing reverse flow that can cause damage or inefficiency. In pneumatic low-pressure systems, they automatically close when back pressure is detected, protecting equipment and ensuring safe operation.Q: What types of media can these check valves handle?

A: These valves are specifically designed to be compatible with a wide variety of media, including gases, water, oil, acids, and bases. Their stainless steel construction ensures excellent corrosion resistance, making them suitable for harsh or corrosive environments.Q: When should I select a stainless steel check valve over other materials?

A: Stainless steel check valves are preferable when systems are exposed to corrosive substances or need to withstand temperature fluctuations. They are an excellent choice for applications involving acids, alkaline solutions, or when long service life and minimal maintenance are priorities.Q: Where are these check valves commonly used in India?

A: These check valves are widely employed in chemical plants, water treatment facilities, oil and gas refineries, and industrial pneumatic lines across India. Their adaptability to handle diverse media makes them popular among manufacturers, fabricators, and traders alike.Q: What is the installation process for these check valves?

A: The installation involves aligning the check valve with the piping system according to the flow direction marked on the valve body. Proper sealing and tightening are crucial to maintain performance and prevent leakage, and installation should always follow manufacturers guidelines.Q: What are the key benefits of using stainless steel check valves sourced from a trusted supplier?

A: Purchasing from a reliable manufacturer or supplier in India ensures consistent quality, reliable product support, timely availability, and often customization options tailored to specific system requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free