High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C

Product Details:

- Material Steel

- Technique Hot Rolled

- Grade 1.3343 / HS6-5-2C

- Specific Use Construction

- Finish Polished

- Application Industrial, Manufacturing, Tooling, Automotive, Engineerinf, Steel, etc.

- Click to view more

High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C Price And Quantity

- 1 Number

- 5000 INR/Number

High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C Product Specifications

- 1.3343 / HS6-5-2C

- Steel

- Hot Rolled

- Industrial, Manufacturing, Tooling, Automotive, Engineerinf, Steel, etc.

- Construction

- Polished

High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C Trade Information

- Letter of Credit at Sight (Sight L/C), Cheque

- Central America, Asia, North America, South America, Eastern Europe, Western Europe, Middle East, Australia, Africa

- All India

Product Description

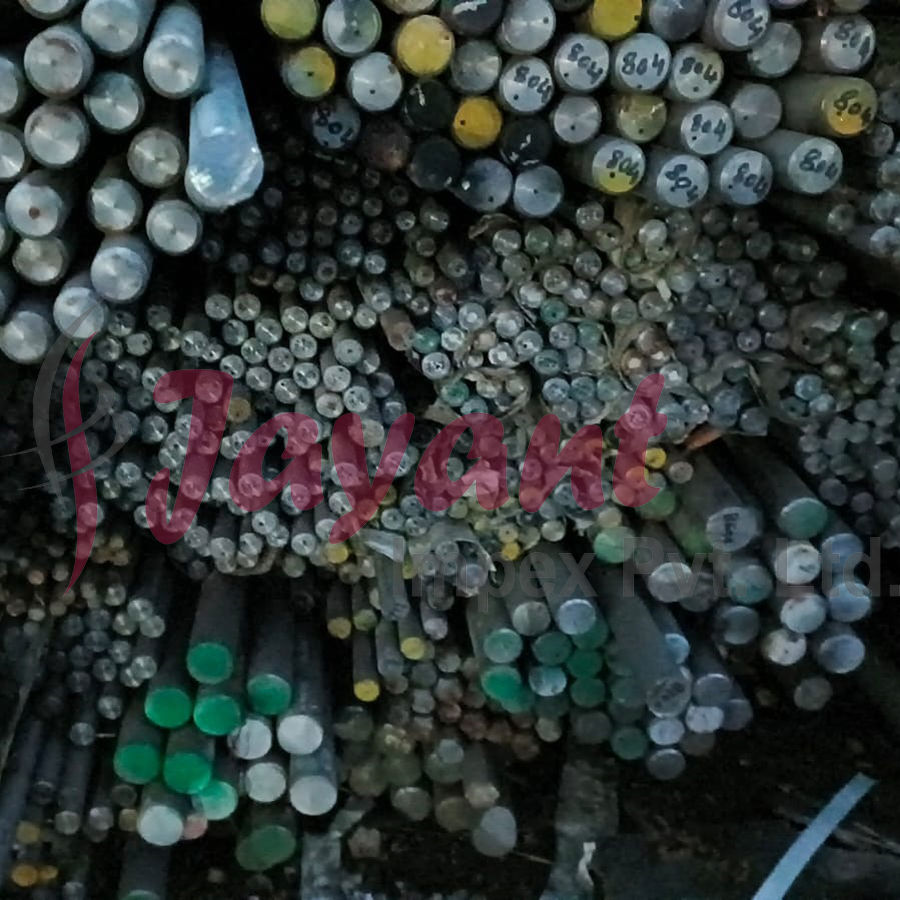

1.3343 Alloy Steel Round Bar, HS6-5-2C Rods, Bars (Normalised, Austenitise, Quench, Double Temper)

Jayant Impex can offer VACUUM DEGASSING (VD) route Alloy Steel 1.3343 Round Bars, 1.3343 Alloy Steel Round Forged Bars, 1.3343 Double Temper Forged Rods, 1.3343 Black Round Bars, 1.3343 Aircraft Quench Bright Round Bars, 1.3343 Normalised Rolled Round Bars, 1.3343 Austenitise Peeled Round Bars, 1.3343 Proof Machined Round Bars, 1.3343 Threaded Round Bars, 1.3343 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. Produced from Scrap Melting in form of Billet, Continuous Cast Billet, Bar, Rods, Round, Flat, Square, Round Corner Square(RCS), Straight Corner Square(SCS), Rectangular, Slabs, Blocks, Hexagonal, Hollow, Concast, Forged, Rolled, Black, Bright, Peeled, Proof Machined, Shafting (Shafts), Plate, Sheet, Coil, Circle, Strip, Foil, Ring (Seamless, Welded, Forged, Rolled), Tube, Tubing, Pipe, Flange, Fitting, Fastener, Stud or Threaded Rod, Bolt, Screw, Nut, Washer, Rivet, Circlip, Retaining Ring, Pin, Threaded Inserts, Standoffs, Spacers, Forgings, Machined Part, Welded Compenents, Welding Consumables, Filler Metal Wire Rod, Shims (Shim-Sheets), Wires, Springs, Bearings, Valve, Gasket, Filter, Silencers, Hard Chrome Plated (HCPR) Rod/Shafting, Pre-Honing, Honed Pipe, etc. or Virgin Ferro Alloys.

Specifications for Round Bars: As per AISI, SAE, UNS, ASTM, JIS, SS, UNE, STAS, GOST, PN, NS, UNI, ISO, IS, ONORM, NBN, CSA, GB, CSN, BS, EU, EN, SFS, AFNOR NF, DIN, WNr, NP, CSN

Size Range for 1.3343 Round Bars: 6mm upto 1200mm

Length for 1.3343 Round Bars: 10mm upto 6000mm depending on material grade & size.

Type of 1.3343 Round Bars: Hot Forged & Cold Forged.

Heat Treatment for Round Bars: Hot Rolled, Cold Drawn, Solution Annealed, Oil & Water Quenched / Tempered

Surface Finish for 1.3343 Round Bars: Bright & Black

1.3343 Round Bars End Finish: SHEARED / BANSAW CUT / HOT- CUT WITH GRINDING/ Water Jet Cutting.

From Jayant Impex Pvt Ltd, India, Maharashtra, Khopoli, Mumbai client can avail VACUUM DEGASSING (VD) route Alloy Steel 1.3343 Round Bars, 1.3343 Round Forged Bars, 1.3343 Double Temper Forged Rods, 1.3343 Black Round Bars, 1.3343 Aircraft Quench Bright Round Bars, 1.3343 Normalised Rolled Round Bars, 1.3343 Austenitise Peeled Round Bars, 1.3343 Proof Machined Round Bars, 1.3343 Threaded Round Bars, 1.3343 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc.

Client can procure smaller quantities of Alloy Steel 1.3343 Round Bars online ready stock from us at premium cost in any destination by just sending us an email.

If any requirements for Alloy Steel 1.3343 Round Bars, 1.3343 Alloy Steel Round Forged Bars, 1.3343 Double Temper Forged Rods, 1.3343 Black Round Bars, 1.3343 Aircraft Quench Bright Round Bars,

1.3343 Normalised Rolled Round Bars, 1.3343 Austenitise Peeled Round Bars, 1.3343 Proof Machined Round Bars, 1.3343 Threaded Round Bars, 1.3343 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. kindly do contact us.

Exceptional Cobalt-Free Performance

The 1.3343 / HS6-5-2C grade high-speed tool steel is specifically formulated without cobalt, ensuring effective performance in high-stress applications while remaining cost-efficient. Its composition strikes a balance between hardness, wear resistance, and toughness, making it a preferred material for tasks where consistent, long-lasting results are crucial.

Versatile Applications and Reliable Supply

This steel is widely utilized in manufacturing, automotive, engineering, and construction. Its hot-rolled, polished construction increases its adaptability for tooling, component fabrication, and machining processes. Indian dealers, manufacturers, exporters, and suppliers provide quick access and reliable distribution, supporting diverse industrial requirements.

FAQs of High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C:

Q: How is High Speed Tool Steel Without Cobalt (1.3343 / HS6-5-2C) processed and finished?

A: This steel is produced using a hot rolling technique followed by a polishing process that enhances its surface finish and mechanical properties. The hot rolling increases the steels toughness and workability, while polishing ensures an optimal surface for precision tooling and component fabrication.Q: What are the main benefits of using 1.3343 / HS6-5-2C steel in industrial applications?

A: The principal advantages include superior wear resistance, high toughness, and reliable hardness without the added cost or supply variability associated with cobalt. These features make it ideal for high-performance tooling and engineering applications that demand durability and longevity.Q: When should this cobalt-free high-speed steel be chosen over other grades?

A: It is most suitable when consistent performance, cost-efficiency, and environmental considerations are priorities. Its absence of cobalt also reduces potential supply constraints, making it an excellent choice for manufacturers seeking dependable alternatives for demanding operational environments.Q: Where can I purchase or source 1.3343 / HS6-5-2C tool steel in India?

A: This grade is available from a comprehensive network of dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers across India. Purchasing locally ensures prompt delivery, technical support, and competitive pricing.Q: What specific uses does this steel serve in the engineering and manufacturing sectors?

A: It is primarily used for creating cutting tools, industrial dies, wear-resistant machine parts, high-precision instruments, and automotive components. Its balanced properties allow for high-speed operations and extended tool life, particularly in production environments.Q: How does the absence of cobalt affect the performance and cost of 1.3343 / HS6-5-2C steel?

A: Without cobalt, this steel remains cost-effective while still achieving excellent wear resistance and toughness. The absence of cobalt also mitigates environmental and supply chain concerns, offering a reliable material solution without compromising performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free