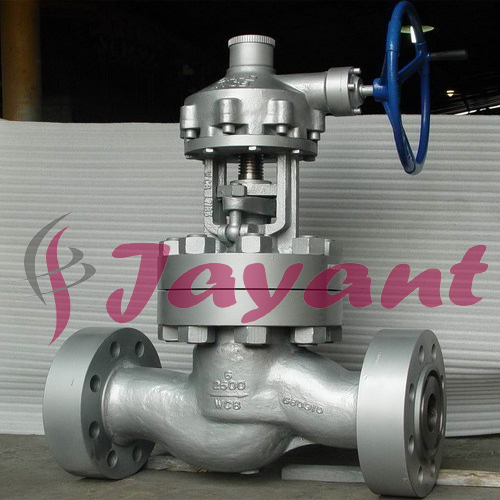

High Pressure Globe Valves

Product Details:

- Application Cooling water systems. Fuel oil systems. Feedwater or chemical feed systems. Boiler and main steam vents and drains. Turbine lube oil system and others.

- Size 1/2 INCH TO 12 INCH

- Product Type High Pressure Globe Valves

- Media Water, Gas, Oil, Base, Acid

- Click to view more

X

High Pressure Globe Valves Price And Quantity

- 1 Number

High Pressure Globe Valves Product Specifications

- Water, Gas, Oil, Base, Acid

- Cooling water systems. Fuel oil systems. Feedwater or chemical feed systems. Boiler and main steam vents and drains. Turbine lube oil system and others.

- 1/2 INCH TO 12 INCH

- High Pressure Globe Valves

High Pressure Globe Valves Trade Information

- Nhava sheva

- Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Week

- 4 Week

- Central America, Australia, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Africa

- All India

Product Description

Globe valves, so-called because of their outside shape, are widely used in plant piping. They are suitable for manual and automatic operation. Unlike the gate valve, globe valve can be used for regulating flow or pressures as well as complete shutoff of flowVersatile Applications Across Industries

These high pressure globe valves are vital components in a wide range of industrial sectors. Their robust design allows them to manage different types of fluids and gases effectively, making them indispensable for cooling, fuel, steam, boiler, and lubricant systems. Their versatility ensures seamless operation and process safety in high-demand settings.

Reliable Flow Control and Regulation

Globe valves are renowned for offering superior throttling and flow regulation. By adjusting the valve, users can easily control the rate and pressure of media passing through pipelines, helping maintain efficient system performance and preventing leaks or pressure surges.

FAQs of High Pressure Globe Valves:

Q: How do high pressure globe valves improve the efficiency of cooling water and boiler systems?

A: High pressure globe valves are specifically designed to provide precise control over fluid flow, enabling users to regulate pressure and flow rates accurately. In cooling water and boiler systems, this translates to optimized energy usage, reduced risk of leakage, and prolonged equipment lifespan.Q: What makes these globe valves suitable for handling diverse media such as water, gas, oil, base, and acid?

A: These valves are constructed from robust, corrosion-resistant materials that accommodate a wide spectrum of media, including both corrosive and non-corrosive substances. Their versatility enables safe and reliable operation across different industrial applications.Q: When should I consider using a globe valve instead of other valve types in my system?

A: Globe valves are ideal when you require accurate throttling or flow regulation rather than simple on/off control. They are particularly well-suited for applications where maintaining precise flow rates or pressure is essential, such as chemical feed, steam vent, or fuel oil systems.Q: Where can I source high pressure globe valves in India?

A: These valves are available through a wide network of dealers, manufacturers, exporters, distributors, and suppliers throughout India. The diverse supply chain ensures local availability and quick turnaround for various industrial needs.Q: What is the typical process for installing globe valves in an industrial pipeline?

A: Installation typically involves selecting the appropriate valve size for your pipeline, ensuring compatibility with the process media, and securely connecting the valve to the pipeline using standard flanged, screwed, or welded connections. It is essential to follow manufacturers guidelines for installation and commissioning to guarantee optimal performance.Q: How are these valves used in turbine lube oil systems and chemical feed applications?

A: In turbine lube oil systems, high pressure globe valves help regulate oil flow, ensuring proper lubrication and system protection. In chemical feed applications, they allow for precise metering and safe delivery of chemicals, supporting process accuracy and personnel safety.Q: What are the main benefits of sourcing globe valves from reputable dealers and manufacturers in India?

A: Partnering with established dealers and manufacturers offers quality assurance, prompt technical support, competitive pricing, and reliable after-sales service. This ensures you receive durable, high-performance products tailored to your application requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free