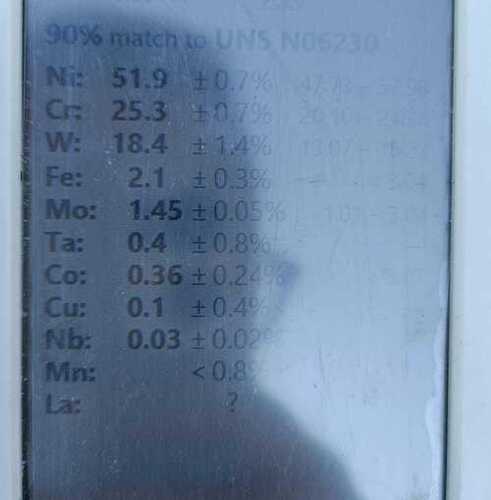

Hayne 230 (Alloy)-UNS N06230

Product Details:

- Product Type Nickel Alloy

- Shape Wire, Square, Bar, Pipe, Plate, Stripe

- Grade Hayne 230 (Alloy)-UNS N06230

- Application Chemical, Steel Making, Petroleum

- Click to view more

Hayne 230 (Alloy)-UNS N06230 Price And Quantity

- 1 Number

Hayne 230 (Alloy)-UNS N06230 Product Specifications

- Chemical, Steel Making, Petroleum

- Wire, Square, Bar, Pipe, Plate, Stripe

- Hayne 230 (Alloy)-UNS N06230

- Nickel Alloy

Hayne 230 (Alloy)-UNS N06230 Trade Information

- Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Yes

- Contact us for information regarding our sample policy

- Western Europe, Eastern Europe, Middle East, Africa, Central America, South America, Asia, North America, Australia

- All India

Product Description

Hayne 230 Alloy Steel Round Bar, Rods, Bars (Normalised, Austenitise, Quench, Double Temper)

Jayant Impex can offer VACUUM DEGASSING (VD) route Alloy Steel Hayne 230 Round Bars, Hayne 230 Alloy Steel Round Forged Bars, Hayne 230 Double Temper Forged Rods, Hayne 230 Black Round Bars, Hayne 230 Aircraft Quench Bright Round Bars, Hayne 230 Normalised Rolled Round Bars, Hayne 230 Austenitise Peeled Round Bars, Hayne 230 Proof Machined Round Bars, Hayne 230 Threaded Round Bars, Hayne 230 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. Produced from Scrap Melting in form of Billet, Continuous Cast Billet, Bar, Rods, Round, Flat, Square, Round Corner Square(RCS), Straight Corner Square(SCS), Rectangular, Slabs, Blocks, Hexagonal, Hollow, Concast, Forged, Rolled, Black, Bright, Peeled, Proof Machined, Shafting (Shafts), Plate, Sheet, Coil, Circle, Strip, Foil, Ring (Seamless, Welded, Forged, Rolled), Tube, Tubing, Pipe, Flange, Fitting, Fastener, Stud or Threaded Rod, Bolt, Screw, Nut, Washer, Rivet, Circlip, Retaining Ring, Pin, Threaded Inserts, Standoffs, Spacers, Forgings, Machined Part, Welded Compenents, Welding Consumables, Filler Metal Wire Rod, Shims (Shim-Sheets), Wires, Springs, Bearings, Valve, Gasket, Filter, Silencers, Hard Chrome Plated (HCPR) Rod/Shafting, Pre-Honing, Honed Pipe, etc. or Virgin Ferro Alloys.

Specifications for Round Bars: As per AISI, SAE, UNS, ASTM, JIS, SS, UNE, STAS, GOST, PN, NS, UNI, ISO, IS, ONORM, NBN, CSA, GB, CSN, BS, EU, EN, SFS, AFNOR NF, DIN, WNr, NP, CSN

Size Range for Hayne 230 Round Bars: 6mm upto 1200mm

Length for Hayne 230 Round Bars: 10mm upto 6000mm depending on material grade & size.

Type of Hayne 230 Round Bars: Hot Forged & Cold Forged.

Heat Treatment for Round Bars: Hot Rolled, Cold Drawn, Solution Annealed, Oil & Water Quenched / Tempered

Surface Finish for Hayne 230 Round Bars: Bright & Black

Hayne 230 Round Bars End Finish: SHEARED / BANSAW CUT / HOT- CUT WITH GRINDING/ Water Jet Cutting.

From Jayant Impex Pvt Ltd, India, Maharashtra, Khopoli, Mumbai client can avail VACUUM DEGASSING (VD) route Alloy Steel Hayne 230 Round Bars, Hayne 230 Round Forged Bars, Hayne 230 Double Temper Forged Rods, Hayne 230 Black Round Bars, Hayne 230 Aircraft Quench Bright Round Bars, Hayne 230 Normalised Rolled Round Bars, Hayne 230 Austenitise Peeled Round Bars, Hayne 230 Proof Machined Round Bars, Hayne 230 Threaded Round Bars, Hayne 230 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc.

Client can procure smaller quantities of Alloy Steel Hayne 230 Round Bars online ready stock from us at premium cost in any destination by just sending us an email.

If any requirements for Alloy Steel Hayne 230 Round Bars, Hayne 230 Alloy Steel Round Forged Bars, Hayne 230 Double Temper Forged Rods, Hayne 230 Black Round Bars, Hayne 230 Aircraft Quench Bright Round Bars, Hayne 230 Normalised Rolled Round Bars, Hayne 230 Austenitise Peeled Round Bars, Hayne 230 Proof Machined Round Bars, Hayne 230 Threaded Round Bars, Hayne 230 Normalized Round Bars, Annealed Round Bars, Heat Treated Round Bars, Quenched (Hardened) & Tempered Round Bars, Age Hardened Rods, Cold drawn & Stress Relieved Rods, Warm Worked Rods, Hex-agonal Rods Treated to ferrite-pearlite structure, etc. kindly do contact us.

Exceptional Performance in Extreme Environments

Hayne 230 (Alloy)-UNS N06230 is engineered to maintain strength and resist oxidation even under severe thermal and chemical exposures. Its robust design allows it to function reliably in high-stress settings such as chemical plants, petrochemical facilities, and steel foundries, ensuring durability and reduced maintenance.

Available in Multiple Forms to Suit Varied Applications

With forms like wire, bar, pipe, plate, square, and stripe, this alloy can be precisely fabricated to fit specific application demands. Its adaptability makes it a top choice for Indian industries, whether used for process piping or manufacturing structural components.

Reliable Supply Chain in India

A robust network of professionalsincluding manufacturers, exporters, suppliers, and fabricatorsensures a consistent and timely provision of Hayne 230 alloy products throughout India. This widespread availability supports ongoing and large-scale projects with ease.

FAQs of Hayne 230 (Alloy)-UNS N06230:

Q: How is Hayne 230 (Alloy)-UNS N06230 typically processed in industrial applications?

A: Hayne 230 can be processed through standard hot and cold working techniques, including rolling, forging, and welding. Its versatility allows it to be formed into wires, bars, pipes, and plates for various end uses in high-temperature environments.Q: What are the primary industrial uses of Hayne 230 alloy in India?

A: This alloy finds critical application in chemical processing, steel manufacturing, and petroleum industries due to its outstanding resistance to oxidation and high-temperature strength.Q: When should a manufacturer choose Hayne 230 (Alloy)-UNS N06230 over other alloys?

A: Manufacturers should select Hayne 230 when exceptional oxidation resistance, structural integrity at high temperatures, and prolonged durability in corrosive atmospheres are required.Q: Where can I source Hayne 230 (Alloy)-UNS N06230 in India?

A: The alloy is readily available in India through an extensive network of dealers, distributors, exporters, manufacturers, and suppliers, ensuring easy procurement for both small-scale and large industrial needs.Q: What benefits does using Hayne 230 alloy offer for steel making and chemical processing?

A: Using Hayne 230 increases component longevity, minimizes maintenance frequency, and maximizes reliability due to its high resistance to wear, corrosion, and thermal deformation.Q: Who are the key suppliers and intermediaries for Hayne 230 alloy products in India?

A: A broad ecosystem including producers, fabricators, retailers, traders, and wholesalers supply a comprehensive range of Hayne 230 forms for various industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free