Expansion Joint

10000 INR/Piece

Product Details:

- Grade SS 316

- Application Metal Bellows are used to absorb thermal movements of pressure vessels, piping, and ducting systems while retaining system design pressure at system design temperature. Regardless of the manufacturer and manufacturing method, the metal bellows terminology is consistent.

- Product Type Other

- Material SS 316

- Standard Other

- Shape Round, Square, Rectangular, Oval, Reducing

- Surface Black, Painted, Galvanized

- Click to view more

X

Expansion Joint Price And Quantity

- 10000 INR/Piece

- 10000.00 - 100000.00 INR/Piece

- 1 Piece

Expansion Joint Product Specifications

- Silver

- SS 316

- Metal Bellows are used to absorb thermal movements of pressure vessels, piping, and ducting systems while retaining system design pressure at system design temperature. Regardless of the manufacturer and manufacturing method, the metal bellows terminology is consistent.

- ERW

- SS 316

- Other

- Black, Painted, Galvanized

- Other

- Round, Square, Rectangular, Oval, Reducing

- 10 Bar

Expansion Joint Trade Information

- Nhava Sheva

- 1 Piece Per Month

- 2 Week

- Contact us for information regarding our sample policy

- Wooden Box Packing, Corrugated Box, freely

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- All India

- ISO Certification

Product Description

Expansion jointsare installed in a piping system to absorb vibration and shock. They also have advantages such as reducing the noise and compensate caused by misalignment. Special expansion joints can also be designed for thermal expansion in hot applications.Expansion joints are usually made from metal, rubber, or braided. (Braided stainless steel hoses with flexible or metal liners are not expansion joints.) Metal expansion joints are mostly used in applications with the issue of thermal expansion. If the temperature of the pipe increases, the metal expansion joint compresses to compensate for the movement and alleviate stress from the pipe. There are a variety of material choices for metallic bellows, including stainless steel and nickel alloys.Engineered for Thermal Movement

Expansion joints with SS 316 metal bellows are essential in industrial piping and pressure vessel systems. Their precision engineering enables them to absorb thermal expansion and contraction caused by fluctuating temperatures. This ensures that the integrity and efficiency of the overall system are preserved, minimizing the risk of damage or leaks due to stress or pressure changes.

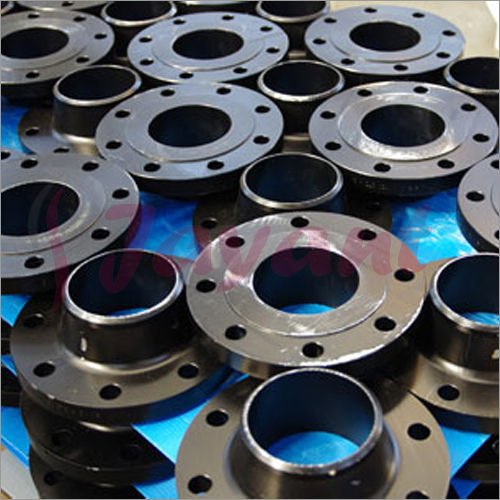

Versatile Surface Finishes and Shapes

Our expansion joints are available in black, painted, and galvanized finishes to match specific corrosion resistance and aesthetic demands. Shapes such as round, square, oval, rectangular, and reducing make these joints adaptable to various piping configurations. This flexibility makes them suitable for new installations and retrofitting existing systems.

Trusted Supplier Across India

As a dealer, supplier, and exporter based in India, we cater to a diverse clientele ranging from fabricators to wholesalers. Our expansive network and robust production capabilities ensure timely delivery and reliable technical support. Whether you need standard sizes or custom configurations, our team delivers solutions for complex industrial challenges.

FAQs of Expansion Joint:

Q: How are SS 316 expansion joints manufactured for industrial use?

A: SS 316 expansion joints are produced using the Electric Resistance Welding (ERW) method, which results in strong, durable weld seams. This process ensures the joints can withstand high pressures and thermal movement, making them ideal for industrial piping and ducting systems.Q: What makes SS 316 a suitable material for expansion joints?

A: Stainless Steel 316 (SS 316) offers exceptional resistance to corrosion, high temperatures, and chemical exposure. This makes it especially appropriate for environments where metal bellows must perform under thermal cycling and high pressure (up to 10 Bar).Q: When should expansion joints with metal bellows be used in a piping system?

A: Expansion joints with metal bellows should be incorporated whenever a piping, vessel, or ducting system is subject to thermal expansion and contraction. These joints protect the integrity of the system by absorbing movements that could otherwise cause stress or leaks.Q: Where are your SS 316 expansion joints supplied and installed?

A: We supply and support expansion joint installations across India, partnering with fabricators, contractors, and industrial clients in sectors such as chemical processing, energy, and infrastructure. Our dealer and distributor network ensures local availability and technical assistance.Q: What are the available shapes and finishes for these expansion joints?

A: Our expansion joints come in a variety of shapesround, square, rectangular, oval, and reducingto suit different system requirements. Finish options include black, painted, and galvanized surfaces, all maintaining the products silver color and corrosion resistance.Q: How does using a metal bellows expansion joint benefit my pressure vessel or piping system?

A: Utilizing metal bellows expansion joints helps absorb thermal movements, preventing damage and extending the service life of your pressure vessels and piping. They maintain design pressure at specified temperatures and ensure system safety and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free