-

Our Products

- Steel Bar

- Alloy Steel Round Bar

- High Speed Tool Steel : 1.3243 / HS6-5-3-5

- Brass Bar

- Structural Alloy Steel : 18X2H4MA

- Tool Steel : 1.2067 / 102Cr6

- F5 / F11 / F12 / F22 / F91 Round Bar

- Cobalt-Chromium Alloy : 2.4778 / G-CoCr28

- Tool Steel : 1.2367 / X38CrMoV5-3

- Nickel Alloy : Alloy 617 / 2.4663 / NiCr23Co12Mo / N06617

- Tool Steel : 1.2162 / 21MnCr5

- Austenitic Heat Resistance Nickel Alloy : Alloy 600 / 2.4816 / NiCr15Fe / N06600

- SAE AISI 8640 Round Bar

- Austenitic Heat Resisting Nickel Alloy : Alloy 625 / 2.4856 / NiCr22Mo9Nb / N006525

- Austenitic Heat Resisting Nickel Alloy : Alloy 601 / 2.4851 / NiCr23Fe15 / N06601

- Heat Resistant Casting Alloy : 2.4879 / G-NiCr28W

- Austenitic Alloy : 2.4955 / NiFe25Cr20NbTi

- Tool Steel : 1.2080 / X210Cr12

- Tool Steel : 1.2834 / 105V

- Tungsten Carbide Flat Bars

- Cobalt Alloy : Alloy 25 / 2.4964 / CoCr20W15Ni / R30605

- Tool Steel : 1.2344 / X40CrMoV5-1

- Stellite 12 (HS-12)

- Tool Steel : 1.2661 / 38CrCoWV18-17-17

- Tool Steel : 1.2842 / 90MnCrV8

- High Speed Tool Steel Without Cobalt : 1.3325 / HS0-4-1

- Waspaloy Alloy

- Tool Steel : 1.2379 / X153CrMoV12

- High Speed Tool Steel With Cobalt : 1.3247 / HS2-9-1-8

- Tool Steel : 1.2825 / 95MnWCr5

- Structural Alloy Steel : 20X2H4A

- SS 304 Injection Tube (Half Hard)

- Nickel Alloy : Alloy 690 / 2.4642 / NiCr29Fe / N06690

- Alloy Steel FL-LA 2557.1 SX (FAG)

- Tool Steel : 1.2002 / 125Cr2

- Super Duplex Steel Round Bar

- Tool Steel : 1.2343 / X37CrMoV5-1

- Nickel Alloy : 2.4878 / NiCr25Co20TiMo

- Nickel Alloy : Alloy 718 / 2.4668 / NiCr19NbMo / N07718

- Austenitic Manganese Steel For Casting : 1.3415 / GX120MnMo7-1

- Nickel Alloy : Alloy 80 A / 2.4952 / NiCr20TiAl / N07080

- Inconel 939 Ingots, Inconel 939 Extra Low Zr Bars, Inconel 939 Aerospace Scrap

- Austenitic Manganese Steel For Casting : 1.3406 / GX100Mn13

- Stainless Alloy Steel C50TF84 (GE)

- SAE 8640 Alloy Steel

- High Speed Steel Bar

- High Speed Tool Steel Without Cobalt : 1.3351 / HS6-5-4

- FSX 414

- Inconel 625

- High Speed Tool Steel Without Cobalt : 1.3344 / HS6-5-3

- Stainless Steel Round Bar

- Tool Steel : ASTM H12 / 1.2605 / X35CrWMoV5

- Tool Steel : 1.2550 / 60WCrV8

- Nickel Cobalt Alloy Udimet 500 Scrap / U500 Blade Scrap / U500 Blades/Udimet 500 Bars / U500 Round Bar, Rods

- AISI 1144 Round Bars

- Tool Steel : 1.2355 / 50CrMoV13-15

- Nickel Alloy : Alloy C-263 / 2.4650 / NiCo20Cr20MoT / N07263

- Tool Steel : 1.2302 / 35CrMo7

- High Speed Tool Steel Without Cobalt : 1.3327 / HS1-8-1

- Alloy Steel Bar

- High Speed Tool Steel Without Cobalt : 1.3339 / HS6-5-2

- High Speed Tool Steel Without Cobalt : 1.3350 / HS6-6-2

- Austenitic Manganese Steel For Casting : 1.3411 / GX120MnCr18-2

- High Speed Tool Steel Without Cobalt 1.3348 / HS2-9-2

- Nickel Alloy Alloy 333 2.4608 NiCr26MoW N06333

- Austenitic Manganese Steel For Casting : 1.3407 / GX120Mn18

- Carbon And Alloy Steel Bar

- Tool Steel Bar

- Nickel Super Alloy : 2.4654 / NiCr20Co13Mo4Ti3Al

- 17-7PH per AMS 5644

- HSS M35 High Speed Tool Steel

- Tool Steel : 1.2824 / 70MnMoCr8

- Tool Steel : 1.2363 / X100CrMoV5

- Tool Steel : 1.2316 / X38CrMo16

- Tool Steel : 1.2767 / 45NiCrMo16

- Inconel Alloy 725 : N07725

- Tool Steel : 1.2436 / X210CrW12

- Nickel Alloy : Alloy HX / 2.4665 / NiCr19Fe19Nb5Mo3 / N06002

- Pure Tungsten

- Nickel Alloy : Alloy 75 / 2.4951 / NiCr20Ti / N06075

- Inconel 825

- Nickel Alloy : Alloy 90 / 2.4632 / NiCr20Co18Ti / N07090

- High Speed Tool Steel : 1.3244 / HS6-5-3-8

- Tungsten Carbide Strips

- Tool Steel : 1.2738 / 40CrMnNiMo8-6-4

- Tool Steel : 1.2714 / 55NiCrMoV7

- Tool Steel : 1.2581 / X30WCrV93 / H21 / SKD5

- Duplex Steel Round Bar

- High Speed Tool Steel : 1.3207 / HS10-4-3-10

- Tool Steel : 1.2083 / X40Cr14

- Nickel Alloy : Alloy X-750 / 2.4669 / NiCr15Fe7TiAl /N07750

- Nitinol Wire

- High Speed Tool Steel Without Cobalt : 1.3355 / HS18-0-1

- Tool Steel : 1.2235 / 80CrV2

- 409L Pipes And Tubes

- Heat Resistant Casting Alloy : 2.4680 / G-NiCr50Nb

- Austenitic Heat Resisting Nickel Alloy : Alloy 45 / 2.4889 / NiCr28FeSiCe / N06045

- ErNiMo9 Wire / ErNiMo-9 Filler Wires/ ErNiMo9 Welding Electrodes / ErNiMo-9 Wire Rods

- High Speed Tool Steel Without Cobalt : 1.3345 / HS6-5-3C

- Super Duplex Steel Bar

- Inconel : Alloy 825 / 2.4858 / N 08825

- Alloy Special Steel : AISI 4340 / 1.6511 / 36CrNiMo4

- High Speed Tool Steel Without Cobalt : 1.3343 / HS6-5-2C

- AMS 6304 (17-22A)

- Alloy Special Steel : 1.7709 / 21CrMoV5-7

- Aluminium Plate Grade 7075 T-6

- High Speed Tool Steel Without Cobalt : 1.3326 / HS1-4-2

- Grade AMS 5659

- Cronidur 30

- High Speed Tool Steel Without Cobalt : 1.3333 / HS3-3-2

- Nickel Alloy : Alloy 602CA / 2.4633 / NiCr25FeAIY / N06025

- Tool Steel : 1.2365 / 32CrMoV12-28

- 430FR Solenoid Quality Stainless Steel

- Tool Steel : 1.2549 / 50WCrV8

- AISI A7 / SAE A7 : FED QQ-T-570 A7 : ASTM A681 A-7 : UNS T30107

- Stainless Steel AISI 430F

- Cast Nickel : 2.4815 / G-NiCr15

- Austenitic Manganese Steel For Casting : 1.3410 / GX120MnCr13-2

- Austenitic Manganese Steel For Casting : 1.3416 / GX110MnMo13-1

- Austenitic Manganese Steel For Casting : 1.3417 / GX90MnMo14

- Austenitic Manganese Steel For Casting : 1.3425 / GX120MnNi13-3

- Austenitic Manganese Steel For Casting: 1.3802-GX120Mn13

- Carbon Fiber Sheets and Slabs

- Hastelloy X per AMS 5754

- PH13-8Mo per AMS 5629 Type 1

- L-605 per AMS 5759

- Inconel 718 per AMS 5662

- A286 per AMS 5732

- 9310 VAR per AMS 6260

- 9310 VAR per AMS 6265

- Inconel 718 per AMS 5663

- A286 per AMS 5737

- 4340 VAR per AMS 6414

- Pyrowear 53 per AMS 6308

- 15-5PH per AMS 5659 Type 1

- CBS-50 NiL per AMS 6278

- ALUMINIUM BAR 5083

- Aermet 100 per AMS 6532

- 17-4PH VAR per AMS 5622 Type1

- Inconel 903

- Inconel 909

- Inconel 907

- Inconel 800HT

- Nitriding 135M per AMS 6470

- Nitriding 135M per AMS 6471

- Inconel 690

- Hy-Tuf per AMS 6418

- Hy-Tuf per AMS 6425

- Inconel 706

- H13 Round Bar

- B1925 Nickel Cobalt Alloy Scrap

- Stellite 25 (HS-25 / L605)

- Stellite 31 (HS-31)

- Stellite 1 (HS-1)

- Stellite 4 (HS-4)

- Stellite 6 (HS-6)

- Stellite 6B (HS-6B)

- Stellite 19 (HS-19)

- Stellite 21 (HS-21)

- 418 Greek Ascoloy per AMS 5616

- Steel Bar Mar-M 246

- Steel Bar Mar-M 247

- Steel Bar Mar-M 247LC

- Steel Bar Mar-M 509

- Titanium Grade 5 (VAC Quality)

- Titanium Mesh

- Titanium Grade 2 (VAC Quality)

- Hot Work Tool Steel H10

- Hot Work Tool Steel H11

- Hot Work Tool Steel H12

- Hot Work Tool Steel H13

- Hot Work Tool Steel H14

- Hot Work Tool Steel H19

- Hot Work Tool Steel H21

- Hot Work Tool Steel H22

- Hot Work Tool Steel H23

- Custom 455 per AMS 5617

- Steel bar Custom 465 per AMS 5936

- Inconel 617

- Steel Bar AM-355 per AMS 5743

- Hot Work Tool Steel H24

- Hot Work Tool Steel H25

- Hot Work Tool Steel H26

- Hot Work Tool Steel H42

- Steel Bar CM247LC / Mar-M 247 LC

- Mayer bar

- ALLOY SUPER 13CR / UNS S41427

- 1.2360 / X48CrMoV8-1-1

- Steel 1.0718 Round Bar

- 11SMnPb30 Round Bar

- EN1APb / Leaded Round Bar

- AISI / SAE 12L14 Bars

- BS970 1983 230Mo7 Round Bar / Flat Bar / Hex Bar

- BS970 1991 230Mo7Pb Round Bar / Flat Bar / Hex Bar

- DIN 9SMnPb36 Round Bar / Flat Bar / Hex Bar

- JIS SUM24L Round Bar / Hex Bar / Flat Bar

- Maraging C250/Vascomax 250

- MP35N R30035

- L605 Round Bar

- Pyrowear 53 Bars Rods and Rings

- AMS 6308 Bars, Rods and Rings

- Lesco 53 Bars Rods and Rings

- Stainless Steel BS S144

- Stainless Steel BS S145

- Stainless Steel BS S143

- Alloy Steel Def Stan 95-14

- Alloy Spring Steel 55Si2Mn90

- En 45 Alloy Spring Steel

- 55Si2 Alloy Spring Steel

- 55Si7 Alloy Spring Steel

- 56Si7 Alloy Spring Steel

- 1.5026 Alloy Spring Steel

- 55C2 Alloy Spring Steel

- 1.0904 Alloy Spring Steel

- 250A53 Alloy Spring Steel

- AISI 9255 Alloy Spring Steel

- 250A58 Alloy Spring Steel

- AISI 9260 Alloy Spring Steel

- 61SiCr7 Alloy Spring Steel

- 1.7108 Alloy Spring Steel

- 60S2G Alloy Spring Steel

- SAE 4150 Alloy Steel

- Alloy Steel 20X2H4A

- 20MnV6 Alloy Steel

- S1 Alloy Tool Steel

- AISI SS444 Bars

- 21CrMoV5-7 Alloy Steel

- SAE 4130 Alloy Steel

- 18X2H4MA Alloy Steel

- ISO 5832-9 Stainless Steel

- Custom 450 Stainless Steel

- 16Mo3 Alloy Steel

- 15CDV6 Alloy Steel

- 300M Alloy Steel

- En26 Alloy Steel

- En28 Alloy Steel

- 17CrNiMo6 Alloy Steel

- H10 Tool Steel

- 13CrMo4-5 Alloy Steel

- 31CrMoV9 Alloy Steel

- 30CrNiMo8 Alloy Steel

- SAE 4340 Alloy Steel

- AISI S7 Tool Steel

- En25 Alloy Steel

- 35NiCrMoV11-5 Alloy Steel

- 33NiCrMoV14-5 Alloy Steel

- SAE 4320 Alloy Steel

- Jethete M152 Stainless Steel

- SAE 5160 Spring Steel

- 34CrNiMo6 Alloy Steel

- Stainless Steel 422

- 1.4418 Stainless Steel

- 17CrNi6-6 Alloy Steel

- EN40B Nitriding Alloy Steel

- 34CrMo4 Steel

- SAE 4330V Alloy Steel

- M50NiL Alloy Steel

- Alloy Steel B50TF211 (GE)

- Stainless Alloy Steel MS-198 (MRC)

- MSRR 6113 (Rolls Royce Grade)

- Alloy Steel CPW 492 (Pratt & Whitney Grade)

- Alloy Steel PWA 36140 (Pratt & Whitney)

- EMS 35 (Timken Aerospace)

- Multimet N155

- Haynes 188

- Inconel 783

- Inconel 700

- Inconel 100

- Inconel X-750

- GTD-111 Low Zr

- GTD-141 Alloy

- GTD-741 Alloy

- GTD-241 Alloy

- GTD-444 Alloy

- Cobalt Alloy UmCo 50

- Cobalt Alloy UmCo 51

- Udimet 520

- Udimet 700

- Udimet 720

- Dowel Pins

- Industrial Bolts

- Plastic Bar

- Steel Coils

- Circle Clips

- Corten Steel Plate

- Industrial Flanges

- Solenoid Valves

- Solenoid Valves

- Industrial Solenoid Valves

- KNIFE GATE VALVE WITH URETHANE DEFLECTOR CONE

- PTFE Butterfly Valve With Pneumatic

- Needle valve

- gate valves

- Ball Valve Actuator

- V NOTCH KNIFE GATE VALVE

- manifold valve

- Irrigation Valve

- WCB Ball Valve

- High Orifice solenoid valve

- Oil Danfoss Solenoid Valve MD1D-RK/59N-D DMS 160L8002 For Hydraulic

- Industrial Washer

- Fasteners

- Fitting Bushing

- Drop In Anchor

- Hex Weld Nut (Mild-Steel)

- Nylock Nut

- B7 Studs

- CE Marked Lifting Eye Bolt Galvanized

- External Threaded Taper Dowel Pin

- T Nut Mild Steel

- Double Threaded Grub Screw

- Nylon Wheel/ Roller with 6204 Bearing

- Blind Rivet / Pop Rivet

- Spring Nut

- Cadmium Plated : Hex Bolt - Hex Nut - Plain Washer

- Wing Nut

- Serrated Flange Nuts

- Butt Weld Pipe Reducer

- Stub End

- Allen Key

- Allen Cap Screw Half Threaded

- Dowel Pin

- Ejector Pins

- Allen Grub Screw

- Nitrile Rubber Flat Seal

- Allen CSK Screws SS 304

- Helicoil Insert SS 304

- Hex Nut ASTM A194 Gr.2H

- PTFE Coated Studs

- Socket Weld Elbow

- Full Threaded Stud ASTM A193 Gr.B7

- Lag Screw / Coach Screw / Lag Bolt / Coach Bolt

- White Tungsten Wire

- Nylon Hex Bolt-Nut With Plain Washers

- Rivet Nut

- Km Lock Nut

- Cross Pipe Fitting

- Butt Weld End Caps

- Nickel Plated Socket Head Cap Screw

- Knurled Nuts

- Insert Nut

- Pipe Fitting Union

- Zinc Plated Rings

- Nut Inserts M4 Brass

- Full Threaded Stud with Heavy Hex Nut ASTM A193 Gr.B16

- Tungsten Balls

- Stainless Steel clamp

- Valves

- three way ball valve

- Controlled Dividing Breech

- ZERO VELOCITY VALVE

- Cast Iron Reflux Valves

- Steam Jacketed Valve

- LUBRICATED PLUG VALVE

- GLOBE VALVE (SAMSON)

- Knife Gate Valve

- three piece ball valve

- Actuated valves

- Changeover valve

- 3 way valve

- Check Valve

- GEAR OPERATED BUTTERFLY VALVE

- Double hydrant valve

- Globe Valves

- Pneumatic Flow Control Valve

- Double Block Bleed Valve

- thermostatic expansion Valve

- Pneumatic Knife Gate Valves/ Air Powered Pneumatic Knife Gate Valve/ Flow Control Pneumatic Knife Gate Valve/ Precise Control Pneumatic Knife Gate Valves

- ECCENTRIC BUTTERFLY VALVE (SAMSON)

- Top Entry Ball valve

- Carbon Alloy Steel Valve

- Angle control valve

- Tamper Proof Air Valves

- Thermodynamic Steam Trap

- Nuclear Valves

- Bellow seal valve

- Trunnion Valves

- Sandwich Valve

- Louver Dampers

- Dome Valve

- Relay Valve

- weld on ball ends

- Bonnet Valve

- Choke Valves

- Wedge Gate Valves

- Dispensing valve

- Monoblock Valve

- Breeching Inlet Valve

- Flap Valves

- Foot Valves

- Deluge Valves

- Butterfly Valve Handles

- Carbon Steel Globe Valve

- Bronze Globe Valve

- Cast Steel Globe Valves

- Din Globe Valves

- Forged Steel Globe Valve

- High Pressure Globe Valves

- Industrial Globe Valves

- Stainless Steel Globe Valve

- Cast gate valve

- Cast Iron Air Valve

- Cast Iron Foot Valve

- Control valve

- Cast Iron Globe Valve

- Cast Iron Non Return Valve

- Cast Iron Plug Valve

- Cast Iron Swing Valve

- Cast Stainless Steel Valve

- Cast Steel Check Valve

- Cast Steel Gate Valve

- Electric Valve Actuators

- Pneumatic Pinch Valve

- Slurry valves

- Sluice Valve

- Disc Check Valves

- TRUNNION BALL VALVES

- BRONZE GATE VALVE

- Actuators Ball Valve

- Bronze Ball Valve

- Bronze Check Valve

- Double Beat Valves

- Stainless Steel Check Valves

- Air cushion valves

- Air Lock Valves

- Boiler Mounting Valve

- Sight Glass Valve

- Blow Down Valve

- Double Window Sight Glass

- Pump Control Valves

- Pulp Valve

- Block Valve

- Ball Float Steam Trap

- Dump Valve

- Rotary Valves

- Breather Valves

- Plug Valves

- STORM VALVE

- Industrial Fastener

- ASTM A453 Grade 660B Fasteners, ASTM A453 Grade 660B Bolts, Grade 660B Nuts/ Grade 660B Studs

- ASTM A891 Type 1 Fasteners, Bolts, Nuts & Studs

- ASTM A453 Grade 660D Fasteners, ASTM A453 Grade 660D Bolts, Grade 660D Nuts/ Grade 660D Studs

- AMS 5734 Fasteners

- ASTM F2281 660 Fasteners, Bolts, Nuts & Studs

- ASTM A891 Type 2 Fasteners, Bolts, Nuts & Studs

- ASTM A638 660 Type 2 Fasteners, Bolts, Nuts & Studs

- ASTM A638 660 Type 1 Fasteners, Bolts, Nuts & Studs

- ASTM A453 Grade 660A Fasteners, ASTM A453 Grade 660A Bolts, Grade 660A Nuts/ Grade 660A Studs

- ASTM A453 Grade 660C Fasteners, ASTM A453 Grade 660C Bolts, Grade 660C Nuts/ Grade 660C Studs

- 1.4980 Stainless Steel Fasteners

- Alloy A286 Fasteners

- Inconel 718 Fasteners

- Steel Sheets And Plate

- Industrial Stainless Steel Sheets

- Stainless Steel Plain Plates

- Stainless Steel Sheet

- Industrial Stainless Steel Plates

- Bimetallic Sheet

- Stainless Steel Plate SS 304 (AISI 304 / 1.4301 / X5CrNi18-10 / S30400)

- Stainless Steel Plate Sheets

- Syndanio sheet

- Beryllium shielding finger Strip

- Condensed pot

- Stainless Steel Flexible Hose Pipe

- Beryllium sheet

- Cold rolled non-oriented

- Brass Scrap

- BRASS CDA UNS C27451 SCRAP / BRASS CDA UNS C27451 BAR / BRASS CDA UNS C27451 PLATE

- BRASS CDA UNS C85450 SCRAP / BRASS CDA UNS C85450 BAR / BRASS CDA UNS C85450 PLATE

- BRASS CDA UNS C85400 SCRAP / BRASS CDA UNS C85400 BAR / BRASS CDA UNS C85400 PLATE

- BRASS CDA UNS C47000 SCRAP / BRASS CDA UNS C47000 BAR / BRASS CDA UNS C47000 PLATE

- BRASS CDA UNS C84030 SCRAP / BRASS CDA UNS C84030 BAR / BRASS CDA UNS C84030 PLATE

- BRASS CDA UNS C84200 SCRAP / BRASS CDA UNS C84200 BAR / BRASS CDA UNS C84200 PLATE

- BRASS CDA UNS C33500 SCRAP / BRASS CDA UNS C33500 BAR / BRASS CDA UNS C33500 PLATE

- BRASS CDA UNS C84500 SCRAP / BRASS CDA UNS C84500 BAR / BRASS CDA UNS C84500 PLATE

- BRASS CDA UNS C49350 SCRAP / BRASS CDA UNS C49350 BAR / BRASS CDA UNS C49350 PLATE

- BRASS CDA UNS C46400 SCRAP / BRASS CDA UNS C46400 BAR / BRASS CDA UNS C46400 PLATE

- BRASS CDA UNS C42500 SCRAP / BRASS CDA UNS C42500 BAR / BRASS CDA UNS C42500 PLATE

- BRASS CDA UNS C84010 SCRAP / BRASS CDA UNS C84010 BAR / BRASS CDA UNS C84010 PLATE

- BRASS CDA UNS C83450 SCRAP / BRASS CDA UNS C83450 BAR / BRASS CDA UNS C83450 PLATE

- BRASS CDA UNS C45470 SCRAP / BRASS CDA UNS C45470 BAR / BRASS CDA UNS C45470 PLATE

- BRASS CDA UNS C83400 SCRAP / BRASS CDA UNS C83400 BAR / BRASS CDA UNS C83400 PLATE

- BRASS CDA UNS C42000 SCRAP / BRASS CDA UNS C42000 BAR / BRASS CDA UNS C42000 PLATE

- BRASS CDA UNS C43000 SCRAP / BRASS CDA UNS C43000 BAR / BRASS CDA UNS C43000 PLATE

- BRASS CDA UNS C43600 SCRAP / BRASS CDA UNS C43600 BAR / BRASS CDA UNS C43600 PLATE

- BRASS CDA UNS C44750 SCRAP / BRASS CDA UNS C44750 BAR / BRASS CDA UNS C44750 PLATE

- BRASS CDA UNS C40850 SCRAP / BRASS CDA UNS C40850 BAR / BRASS CDA UNS C40850 PLATE

- BRASS CDA UNS C43500 SCRAP / BRASS CDA UNS C43500 BAR / BRASS CDA UNS C43500 PLATE

- BRASS CDA UNS C41120 SCRAP / BRASS CDA UNS C41120 BAR / BRASS CDA UNS C41120 PLATE

- BRASS CDA UNS C36500 SCRAP / BRASS CDA UNS C36500 BAR / BRASS CDA UNS C36500 PLATE

- BRASS CDA UNS C37710 SCRAP / BRASS CDA UNS C37710 BAR / BRASS CDA UNS C37710 PLATE

- BRASS CDA UNS C40500 SCRAP / BRASS CDA UNS C40500 BAR / BRASS CDA UNS C40500 PLATE

- BRASS CDA UNS C38000 SCRAP / BRASS CDA UNS C38000 BAR / BRASS CDA UNS C38000 PLATE

- BRASS CDA UNS C43400 SCRAP / BRASS CDA UNS C43400 BAR / BRASS CDA UNS C43400 PLATE

- BRASS CDA UNS C36000 SCRAP / BRASS CDA UNS C36000 BAR / BRASS CDA UNS C36000 PLATE

- BRASS CDA UNS C37700 SCRAP / BRASS CDA UNS C37700 BAR / BRASS CDA UNS C37700 PLATE

- BRASS CDA UNS C83810 SCRAP / BRASS CDA UNS C83810 BAR / BRASS CDA UNS C83810 PLATE

- BRASS CDA UNS C85200 SCRAP / BRASS CDA UNS C85200 BAR / BRASS CDA UNS C85200 PLATE

- BRASS CDA UNS C84000 SCRAP / BRASS CDA UNS C84000 BAR / BRASS CDA UNS C84000 PLATE

- BRASS CDA UNS C49355 SCRAP / BRASS CDA UNS C49355 BAR / BRASS CDA UNS C49355 PLATE

- BRASS CDA UNS C84020 SCRAP / BRASS CDA UNS C84020 BAR / BRASS CDA UNS C84020 PLATE

- BRASS CDA UNS C83470 SCRAP / BRASS CDA UNS C83470 BAR / BRASS CDA UNS C83470 PLATE

- BRASS CDA UNS C44300 SCRAP / BRASS CDA UNS C44300 BAR / BRASS CDA UNS C44300 PLATE

- BRASS CDA UNS C40400 SCRAP / BRASS CDA UNS C40400 BAR / BRASS CDA UNS C40400 PLATE

- BRASS CDA UNS C37100 SCRAP / BRASS CDA UNS C37100 BAR / BRASS CDA UNS C37100 PLATE

- BRASS CDA UNS C42220 SCRAP / BRASS CDA UNS C42220 BAR / BRASS CDA UNS C42220 PLATE

- BRASS CDA UNS C85500 SCRAP / BRASS CDA UNS C85500 BAR / BRASS CDA UNS C85500 PLATE

- BRASS CDA UNS C83600 SCRAP / BRASS CDA UNS C83600 BAR / BRASS CDA UNS C83600 PLATE

- BRASS CDA UNS C49255 SCRAP / BRASS CDA UNS C49255 BAR / BRASS CDA UNS C49255 PLATE

- BRASS CDA UNS C49250 SCRAP / BRASS CDA UNS C49250 BAR / BRASS CDA UNS C49250 PLATE

- BRASS CDA UNS C42520 SCRAP / BRASS CDA UNS C42520 BAR / BRASS CDA UNS C42520 PLATE

- BRASS CDA UNS C41500 SCRAP / BRASS CDA UNS C41500 BAR / BRASS CDA UNS C41500 PLATE

- BRASS CDA UNS C40410 SCRAP / BRASS CDA UNS C40410 BAR / BRASS CDA UNS C40410 PLATE

- BRASS CDA UNS C40820 SCRAP / BRASS CDA UNS C40820 BAR / BRASS CDA UNS C40820 PLATE

- BRASS CDA UNS C38500 SCRAP / BRASS CDA UNS C38500 BAR / BRASS CDA UNS C38500 PLATE

- BRASS CDA UNS C36300 SCRAP / BRASS CDA UNS C36300 BAR / BRASS CDA UNS C36300 PLATE

- BRASS CDA UNS C48500 SCRAP / BRASS CDA UNS C48500 BAR / BRASS CDA UNS C48500 PLATE

- BRASS CDA UNS C41100 SCRAP / BRASS CDA UNS C41100 BAR / BRASS CDA UNS C41100 PLATE

- BRASS CDA UNS C42600 SCRAP / BRASS CDA UNS C42600 BAR / BRASS CDA UNS C42600 PLATE

- BRASS CDA UNS C85700 SCRAP / BRASS CDA UNS C85700 BAR / BRASS CDA UNS C85700 PLATE

- BRASS CDA UNS C85550 SCRAP / BRASS CDA UNS C85550 BAR / BRASS CDA UNS C85550 PLATE

- BRASS CDA UNS C84800 SCRAP / BRASS CDA UNS C84800 BAR / BRASS CDA UNS C84800 PLATE

- BRASS CDA UNS C83800 SCRAP / BRASS CDA UNS C83800 BAR / BRASS CDA UNS C83800 PLATE

- BRASS CDA UNS C48600 SCRAP / BRASS CDA UNS C48600 BAR / BRASS CDA UNS C48600 PLATE

- BRASS CDA UNS C49360 SCRAP / BRASS CDA UNS C49360 BAR / BRASS CDA UNS C49360 PLATE

- BRASS CDA UNS C49340 SCRAP / BRASS CDA UNS C49340 BAR / BRASS CDA UNS C49340 PLATE

- BRASS CDA UNS C49300 SCRAP / BRASS CDA UNS C49300 BAR / BRASS CDA UNS C49300 PLATE

- BRASS CDA UNS C49260 SCRAP / BRASS CDA UNS C49260 BAR / BRASS CDA UNS C49260 PLATE

- BRASS CDA UNS C48200 SCRAP / BRASS CDA UNS C48200 BAR / BRASS CDA UNS C48200 PLATE

- BRASS CDA UNS C47940 SCRAP / BRASS CDA UNS C47940 BAR / BRASS CDA UNS C47940 PLATE

- BRASS CDA UNS C46500 SCRAP / BRASS CDA UNS C46500 BAR / BRASS CDA UNS C46500 PLATE

- BRASS CDA UNS C46200 SCRAP / BRASS CDA UNS C46200 BAR / BRASS CDA UNS C46200 PLATE

- BRASS CDA UNS C44500 SCRAP / BRASS CDA UNS C44500 BAR / BRASS CDA UNS C44500 PLATE

- BRASS CDA UNS C41300 SCRAP / BRASS CDA UNS C41300 BAR / BRASS CDA UNS C41300 PLATE

- BRASS CDA UNS C44400 SCRAP / BRASS CDA UNS C44400 BAR / BRASS CDA UNS C44400 PLATE

- BRASS CDA UNS C42210 SCRAP / BRASS CDA UNS C42210 BAR / BRASS CDA UNS C42210 PLATE

- BRASS CDA UNS C41110 SCRAP / BRASS CDA UNS C41110 BAR / BRASS CDA UNS C41110 PLATE

- BRASS CDA UNS C41000 SCRAP / BRASS CDA UNS C41000 BAR / BRASS CDA UNS C41000 PLATE

- BRASS CDA UNS C37000 SCRAP / BRASS CDA UNS C37000 BAR / BRASS CDA UNS C37000 PLATE

- BRASS CDA UNS C36010 SCRAP / BRASS CDA UNS C36010 BAR / BRASS CDA UNS C36010 PLATE

- BRASS CDA UNS C83500 SCRAP / BRASS CDA UNS C83500 BAR / BRASS CDA UNS C83500 PLATE

- BRASS CDA UNS C84400 SCRAP / BRASS CDA UNS C84400 BAR / BRASS CDA UNS C84400 PLATE

- BRASS CDA UNS C85800 SCRAP / BRASS CDA UNS C85800 BAR / BRASS CDA UNS C85800 PLATE

- BRASS CDA UNS C84410 SCRAP / BRASS CDA UNS C84410 BAR / BRASS CDA UNS C84410 PLATE

- BRASS CDA UNS C83300 SCRAP / BRASS CDA UNS C83300 BAR / BRASS CDA UNS C83300 PLATE

- BRASS CDA UNS C44250 SCRAP / BRASS CDA UNS C44250 BAR / BRASS CDA UNS C44250 PLATE

- BRASS CDA UNS C42200 SCRAP / BRASS CDA UNS C42200 BAR / BRASS CDA UNS C42200 PLATE

- BRASS CDA UNS C40860 SCRAP / BRASS CDA UNS C40860 BAR / BRASS CDA UNS C40860 PLATE

- BRASS CDA UNS C40810 SCRAP / BRASS CDA UNS C40810 BAR / BRASS CDA UNS C40810 PLATE

- BRASS CDA UNS C24000 SCRAP / BRASS CDA UNS C24000 BAR / BRASS CDA UNS C24000 PLATE

- BRASS CDA UNS C27400 SCRAP / BRASS CDA UNS C27400 BAR / BRASS CDA UNS C27400 PLATE

- BRASS CDA UNS C27450 SCRAP / BRASS CDA UNS C27450 BAR / BRASS CDA UNS C27450 PLATE

- BRASS CDA UNS C26200 SCRAP / BRASS CDA UNS C26200 BAR / BRASS CDA UNS C26200 PLATE

- BRASS CDA UNS C26000 SCRAP / BRASS CDA UNS C26000 BAR / BRASS CDA UNS C26000 PLATE

- BRASS CDA UNS C22000 SCRAP / BRASS CDA UNS C22000 BAR / BRASS CDA UNS C22000 PLATE

- BRASS CDA UNS C21000 SCRAP / BRASS CDA UNS C21000 BAR / BRASS CDA UNS C21000 PLATE

- BRASS CDA UNS C22600 SCRAP / BRASS CDA UNS C22600 BAR / BRASS CDA UNS C22600 PLATE

- BRASS CDA UNS C23000 SCRAP / BRASS CDA UNS C23000 BAR / BRASS CDA UNS C23000 PLATE

- BRASS CDA UNS C25600 SCRAP / BRASS CDA UNS C25600 BAR / BRASS CDA UNS C25600 PLATE

- BRASS CDA UNS C23030 SCRAP / BRASS CDA UNS C23030 BAR / BRASS CDA UNS C23030 PLATE

- BRASS CDA UNS C24080 SCRAP / BRASS CDA UNS C24080 BAR / BRASS CDA UNS C24080 PLATE

- BRASS CDA UNS C23400 SCRAP / BRASS CDA UNS C23400 BAR / BRASS CDA UNS C23400 PLATE

- BRASS CDA UNS C26130 SCRAP / BRASS CDA UNS C26130 BAR / BRASS CDA UNS C26130 PLATE

- BRASS CDA UNS C27000 SCRAP / BRASS CDA UNS C27000 BAR / BRASS CDA UNS C27000 PLATE

- BRASS CDA UNS C27200 SCRAP / BRASS CDA UNS C27200 BAR / BRASS CDA UNS C27200 PLATE

- BRASS CDA UNS C89550 SCRAP / BRASS CDA UNS C89550 BAR / BRASS CDA UNS C89550 PLATE

- BRASS CDA UNS C86400 SCRAP / BRASS CDA UNS C86400 BAR / BRASS CDA UNS C86400 PLATE

- BRASS CDA UNS C86100 SCRAP / BRASS CDA UNS C86100 BAR / BRASS CDA UNS C86100 PLATE

- BRASS CDA UNS C89325 SCRAP / BRASS CDA UNS C89325 BAR / BRASS CDA UNS C89325 PLATE

- BRASS CDA UNS C89841 SCRAP / BRASS CDA UNS C89841 BAR / BRASS CDA UNS C89841 PLATE

- BRASS CDA UNS C87850 SCRAP / BRASS CDA UNS C87850 BAR / BRASS CDA UNS C87850 PLATE

- BRASS CDA UNS C33000 SCRAP / BRASS CDA UNS C33000 BAR / BRASS CDA UNS C33000 PLATE

- BRASS CDA UNS C86300 SCRAP / BRASS CDA UNS C86300 BAR / BRASS CDA UNS C86300 PLATE

- BRASS CDA UNS C86200 SCRAP / BRASS CDA UNS C86200 BAR / BRASS CDA UNS C86200 PLATE

- BRASS CDA UNS C85930 SCRAP / BRASS CDA UNS C85930 BAR / BRASS CDA UNS C85930 PLATE

- BRASS CDA UNS C85910 SCRAP / BRASS CDA UNS C85910 BAR / BRASS CDA UNS C85910 PLATE

- BRASS CDA UNS C89837 SCRAP / BRASS CDA UNS C89837 BAR / BRASS CDA UNS C89837 PLATE

- BRASS CDA UNS C89560 SCRAP / BRASS CDA UNS C89560 BAR / BRASS CDA UNS C89560 PLATE

- BRASS CDA UNS C89540 SCRAP / BRASS CDA UNS C89540 BAR / BRASS CDA UNS C89540 PLATE

- BRASS CDA UNS C89510 SCRAP / BRASS CDA UNS C89510 BAR / BRASS CDA UNS C89510 PLATE

- BRASS CDA UNS C87900 SCRAP / BRASS CDA UNS C87900 BAR / BRASS CDA UNS C87900 PLATE

- BRASS CDA UNS C87700 SCRAP / BRASS CDA UNS C87700 BAR / BRASS CDA UNS C87700 PLATE

- BRASS CDA UNS C87610 SCRAP / BRASS CDA UNS C87610 BAR / BRASS CDA UNS C87610 PLATE

- BRASS CDA UNS C87500 SCRAP / BRASS CDA UNS C87500 BAR / BRASS CDA UNS C87500 PLATE

- BRASS CDA UNS C86550 SCRAP / BRASS CDA UNS C86550 BAR / BRASS CDA UNS C86550 PLATE

- BRASS CDA UNS C86500 SCRAP / BRASS CDA UNS C86500 BAR / BRASS CDA UNS C86500 PLATE

- BRASS CDA UNS C89833 SCRAP / BRASS CDA UNS C89833 BAR / BRASS CDA UNS C89833 PLATE

- BRASS CDA UNS C89842 SCRAP / BRASS CDA UNS C89842 BAR / BRASS CDA UNS C89842 PLATE

- BRASS CDA UNS C89940 SCRAP / BRASS CDA UNS C89940 BAR / BRASS CDA UNS C89940 PLATE

- BRASS CDA UNS C89845 SCRAP / BRASS CDA UNS C89845 BAR / BRASS CDA UNS C89845 PLATE

- BRASS CDA UNS C89844 SCRAP / BRASS CDA UNS C89844 BAR / BRASS CDA UNS C89844 PLATE

- BRASS CDA UNS C89836 SCRAP / BRASS CDA UNS C89836 BAR / BRASS CDA UNS C89836 PLATE

- BRASS CDA UNS C89835 SCRAP / BRASS CDA UNS C89835 BAR / BRASS CDA UNS C89835 PLATE

- BRASS CDA UNS C89831 SCRAP / BRASS CDA UNS C89831 BAR / BRASS CDA UNS C89831 PLATE

- BRASS CDA UNS C89720 SCRAP / BRASS CDA UNS C89720 BAR / BRASS CDA UNS C89720 PLATE

- BRASS CDA UNS C89535 SCRAP / BRASS CDA UNS C89535 BAR / BRASS CDA UNS C89535 PLATE

- BRASS CDA UNS C89530 SCRAP / BRASS CDA UNS C89530 BAR / BRASS CDA UNS C89530 PLATE

- BRASS CDA UNS C89520 SCRAP / BRASS CDA UNS C89520 BAR / BRASS CDA UNS C89520 PLATE

- BRASS CDA UNS C87845 SCRAP / BRASS CDA UNS C87845 BAR / BRASS CDA UNS C87845 PLATE

- BRASS CDA UNS C87800 SCRAP / BRASS CDA UNS C87800 BAR / BRASS CDA UNS C87800 PLATE

- BRASS CDA UNS C89320 SCRAP / BRASS CDA UNS C89320 BAR / BRASS CDA UNS C89320 PLATE

- BRASS CDA UNS C87710 SCRAP / BRASS CDA UNS C87710 BAR / BRASS CDA UNS C87710 PLATE

- BRASS CDA UNS C87600 SCRAP / BRASS CDA UNS C87600 BAR / BRASS CDA UNS C87600 PLATE

- BRASS CDA UNS C87400 SCRAP / BRASS CDA UNS C87400 BAR / BRASS CDA UNS C87400 PLATE

- BRASS CDA UNS C87300 SCRAP / BRASS CDA UNS C87300 BAR / BRASS CDA UNS C87300 PLATE

- BRASS CDA UNS C87200 SCRAP / BRASS CDA UNS C87200 BAR / BRASS CDA UNS C87200 PLATE

- BRASS CDA UNS C86800 SCRAP / BRASS CDA UNS C86800 BAR / BRASS CDA UNS C86800 PLATE

- BRASS CDA UNS C86700 SCRAP / BRASS CDA UNS C86700 BAR / BRASS CDA UNS C86700 PLATE

- BRASS CDA UNS C86350 SCRAP / BRASS CDA UNS C86350 BAR / BRASS CDA UNS C86350 PLATE

- BRASS CDA UNS C85920 SCRAP / BRASS CDA UNS C85920 BAR / BRASS CDA UNS C85920 PLATE

- BRASS CDA UNS C85900 SCRAP / BRASS CDA UNS C85900 BAR / BRASS CDA UNS C85900 PLATE

- NON-LEADED BRASS SCRAP / LEAD FREE BRASS SCRAP / LEADLESS BRASS SCRAP METAL

- BRASS CDA UNS C26800 SCRAP / BRASS CDA UNS C26800 BAR / BRASS CDA UNS C26800 PLATE

- BRASS CDA UNS C31600 SCRAP / BRASS CDA UNS C31600 BAR / BRASS CDA UNS C31600 PLATE

- BRASS CDA UNS C27453 SCRAP / BRASS CDA UNS C27453 BAR / BRASS CDA UNS C27453 PLATE

- BRASS CDA UNS C28000 SCRAP / BRASS CDA UNS C28000 BAR / BRASS CDA UNS C28000 PLATE

- BRASS CDA UNS C28300 SCRAP / BRASS CDA UNS C28300 BAR / BRASS CDA UNS C28300 PLATE

- BRASS CDA UNS C28310 SCRAP / BRASS CDA UNS C28310 BAR / BRASS CDA UNS C28310 PLATE

- BRASS CDA UNS C28320 SCRAP / BRASS CDA UNS C28320 BAR / BRASS CDA UNS C28320 PLATE

- BRASS CDA UNS C28500 SCRAP / BRASS CDA UNS C28500 BAR / BRASS CDA UNS C28500 PLATE

- BRASS CDA UNS C28330 SCRAP / BRASS CDA UNS C28330 BAR / BRASS CDA UNS C28330 PLATE

- BRASS CDA UNS C31200 SCRAP / BRASS CDA UNS C31200 BAR / BRASS CDA UNS C31200 PLATE

- BRASS CDA UNS C31400 SCRAP / BRASS CDA UNS C31400 BAR / BRASS CDA UNS C31400 PLATE

- BRASS CDA UNS C32000 SCRAP / BRASS CDA UNS C32000 BAR / BRASS CDA UNS C32000 PLATE

- BRASS CDA UNS C33200 SCRAP / BRASS CDA UNS C33200 BAR / BRASS CDA UNS C33200 PLATE

- BRASS CDA UNS C34000 SCRAP / BRASS CDA UNS C34000 BAR / BRASS CDA UNS C34000 PLATE

- BRASS CDA UNS C34200 SCRAP / BRASS CDA UNS C34200 BAR / BRASS CDA UNS C34200 PLATE

- BRASS CDA UNS C34500 SCRAP / BRASS CDA UNS C34500 BAR / BRASS CDA UNS C34500 PLATE

- BRASS CDA UNS C35000 SCRAP / BRASS CDA UNS C35000 BAR / BRASS CDA UNS C35000 PLATE

- BRASS CDA UNS C35300 SCRAP / BRASS CDA UNS C35300 BAR / BRASS CDA UNS C35300 PLATE

- BRASS CDA UNS C35330 SCRAP / BRASS CDA UNS C35330 BAR / BRASS CDA UNS C35330 PLATE

- BRASS CDA UNS C35350 SCRAP / BRASS CDA UNS C35350 BAR / BRASS CDA UNS C35350 PLATE

- BRASS CDA UNS C35600 SCRAP / BRASS CDA UNS C35600 BAR / BRASS CDA UNS C35600 PLATE

- Bronze Scrap

- BRONZE CDA UNS C95700 SCRAP / BRONZE CDA UNS C95700 BAR / BRONZE CDA UNS C95700 PLATE

- BRONZE CDA UNS C95810 SCRAP / BRONZE CDA UNS C95810 BAR / BRONZE CDA UNS C95810 PLATE

- BRONZE CDA UNS C95420 SCRAP / BRONZE CDA UNS C95420 BAR / BRONZE CDA UNS C95420 PLATE

- BRONZE CDA UNS C95400 SCRAP / BRONZE CDA UNS C95400 BAR / BRONZE CDA UNS C95400 PLATE

- BRONZE CDA UNS C94800 SCRAP / BRONZE CDA UNS C94800 BAR / BRONZE CDA UNS C94800 PLATE

- BRONZE CDA UNS C98200 SCRAP / BRONZE CDA UNS C98200 BAR / BRONZE CDA UNS C98200 PLATE

- BRONZE CDA UNS C99400 SCRAP / BRONZE CDA UNS C99400 BAR / BRONZE CDA UNS C99400 PLATE

- BRONZE CDA UNS C95410 SCRAP / BRONZE CDA UNS C95410 BAR / BRONZE CDA UNS C95410 PLATE

- BRONZE CDA UNS C99500 SCRAP / BRONZE CDA UNS C99500 BAR / BRONZE CDA UNS C99500 PLATE

- BRONZE CDA UNS C64730 SCRAP / BRONZE CDA UNS C64730 BAR / BRONZE CDA UNS C64730 PLATE

- BRONZE CDA UNS C64700 SCRAP / BRONZE CDA UNS C64700 BAR / BRONZE CDA UNS C64700 PLATE

- BRONZE CDA UNS C55284 SCRAP / BRONZE CDA UNS C55284 BAR / BRONZE CDA UNS C55284 PLATE

- BRONZE CDA UNS C50580 SCRAP / BRONZE CDA UNS C50580 BAR / BRONZE CDA UNS C50580 PLATE

- BRONZE CDA UNS C50700 SCRAP / BRONZE CDA UNS C50700 BAR / BRONZE CDA UNS C50700 PLATE

- BRONZE CDA UNS C98600 SCRAP / BRONZE CDA UNS C98600 BAR / BRONZE CDA UNS C98600 PLATE

- BRONZE CDA UNS C98820 SCRAP / BRONZE CDA UNS C98820 BAR / BRONZE CDA UNS C98820 PLATE

- BRONZE CDA UNS C99350 SCRAP / BRONZE CDA UNS C99350 BAR / BRONZE CDA UNS C99350 PLATE

- BRONZE CDA UNS C98840 SCRAP / BRONZE CDA UNS C98840 BAR / BRONZE CDA UNS C98840 PLATE

- BRONZE CDA UNS C98400 SCRAP / BRONZE CDA UNS C98400 BAR / BRONZE CDA UNS C98400 PLATE

- BRONZE CDA UNS C95720 SCRAP / BRONZE CDA UNS C95720 BAR / BRONZE CDA UNS C95720 PLATE

- BRONZE CDA UNS C95210 SCRAP / BRONZE CDA UNS C95210 BAR / BRONZE CDA UNS C95210 PLATE

- BRONZE CDA UNS C95220 SCRAP / BRONZE CDA UNS C95220 BAR / BRONZE CDA UNS C95220 PLATE

- BRONZE CDA UNS C95300 SCRAP / BRONZE CDA UNS C95300 BAR / BRONZE CDA UNS C95300 PLATE

- BRONZE CDA UNS C95710 SCRAP / BRONZE CDA UNS C95710 BAR / BRONZE CDA UNS C95710 PLATE

- BRONZE CDA UNS C95800 SCRAP / BRONZE CDA UNS C95800 BAR / BRONZE CDA UNS C95800 PLATE

- BRONZE CDA UNS C95500 SCRAP / BRONZE CDA UNS C95500 BAR / BRONZE CDA UNS C95500 PLATE

- BRONZE CDA UNS C95900 SCRAP / BRONZE CDA UNS C95900 BAR / BRONZE CDA UNS C95900 PLATE

- BRONZE CDA UNS C95600 SCRAP / BRONZE CDA UNS C95600 BAR / BRONZE CDA UNS C95600 PLATE

- BRONZE CDA UNS C95820 SCRAP / BRONZE CDA UNS C95820 BAR / BRONZE CDA UNS C95820 PLATE

- BRONZE CDA UNS C95510 SCRAP / BRONZE CDA UNS C95510 BAR / BRONZE CDA UNS C95510 PLATE

- BRONZE CDA UNS C94900 SCRAP / BRONZE CDA UNS C94900 BAR / BRONZE CDA UNS C94900 PLATE

- BRONZE CDA UNS C92400 SCRAP / BRONZE CDA UNS C92400 BAR / BRONZE CDA UNS C92400 PLATE

- BRONZE CDA UNS C95520 SCRAP / BRONZE CDA UNS C95520 BAR / BRONZE CDA UNS C95520 PLATE

- BRONZE CDA UNS C95200 SCRAP / BRONZE CDA UNS C95200 BAR / BRONZE CDA UNS C95200 PLATE

- BRONZE CDA UNS C99720 SCRAP / BRONZE CDA UNS C99720 BAR / BRONZE CDA UNS C99720 PLATE

- BRONZE CDA UNS C69150 SCRAP / BRONZE CDA UNS C69150 BAR / BRONZE CDA UNS C69150 PLATE

- BRONZE CDA UNS C99780 SCRAP / BRONZE CDA UNS C99780 BAR / BRONZE CDA UNS C99780 PLATE

- BRONZE CDA UNS C68100 SCRAP / BRONZE CDA UNS C68100 BAR / BRONZE CDA UNS C68100 PLATE

- BRONZE CDA UNS C90400 SCRAP / BRONZE CDA UNS C90400 BAR / BRONZE CDA UNS C90400 PLATE

- BRONZE CDA UNS C64745 SCRAP / BRONZE CDA UNS C64745 BAR / BRONZE CDA UNS C64745 PLATE

- BRONZE CDA UNS C90900 SCRAP / BRONZE CDA UNS C90900 BAR / BRONZE CDA UNS C90900 PLATE

- BRONZE CDA UNS C66850 SCRAP / BRONZE CDA UNS C66850 BAR / BRONZE CDA UNS C66850 PLATE

- BRONZE CDA UNS C63400 SCRAP / BRONZE CDA UNS C63400 BAR / BRONZE CDA UNS C63400 PLATE

- BRONZE CDA UNS C63380 SCRAP / BRONZE CDA UNS C63380 BAR / BRONZE CDA UNS C63380 PLATE

- BRONZE CDA UNS C63280 SCRAP / BRONZE CDA UNS C63280 BAR / BRONZE CDA UNS C63280 PLATE

- BRONZE CDA UNS C63200 SCRAP / BRONZE CDA UNS C63200 BAR / BRONZE CDA UNS C63200 PLATE

- BRONZE CDA UNS C63020 SCRAP / BRONZE CDA UNS C63020 BAR / BRONZE CDA UNS C63020 PLATE

- BRONZE CDA UNS C63010 SCRAP / BRONZE CDA UNS C63010 BAR / BRONZE CDA UNS C63010 PLATE

- BRONZE CDA UNS C63000 SCRAP / BRONZE CDA UNS C63000 BAR / BRONZE CDA UNS C63000 PLATE

- BRONZE CDA UNS C62581 SCRAP / BRONZE CDA UNS C62581 BAR / BRONZE CDA UNS C62581 PLATE

- BRONZE CDA UNS C62580 SCRAP / BRONZE CDA UNS C62580 BAR / BRONZE CDA UNS C62580 PLATE

- BRONZE CDA UNS C62300 SCRAP / BRONZE CDA UNS C62300 BAR / BRONZE CDA UNS C62300 PLATE

- BRONZE CDA UNS C62500 SCRAP / BRONZE CDA UNS C62500 BAR / BRONZE CDA UNS C62500 PLATE

- BRONZE CDA UNS C62400 SCRAP / BRONZE CDA UNS C62400 BAR / BRONZE CDA UNS C62400 PLATE

- BRONZE CDA UNS C62200 SCRAP / BRONZE CDA UNS C62200 BAR / BRONZE CDA UNS C62200 PLATE

- BRONZE CDA UNS C61900 SCRAP / BRONZE CDA UNS C61900 BAR / BRONZE CDA UNS C61900 PLATE

- BRONZE CDA UNS C61800 SCRAP / BRONZE CDA UNS C61800 BAR / BRONZE CDA UNS C61800 PLATE

- BRONZE CDA UNS C61550 SCRAP / BRONZE CDA UNS C61550 BAR / BRONZE CDA UNS C61550 PLATE

- BRONZE CDA UNS C61500 SCRAP / BRONZE CDA UNS C61500 BAR / BRONZE CDA UNS C61500 PLATE

- BRONZE CDA UNS C61400 SCRAP / BRONZE CDA UNS C61400 BAR / BRONZE CDA UNS C61400 PLATE

- BRONZE CDA UNS C61300 SCRAP / BRONZE CDA UNS C61300 BAR / BRONZE CDA UNS C61300 PLATE

- BRONZE CDA UNS C61000 SCRAP / BRONZE CDA UNS C61000 BAR / BRONZE CDA UNS C61000 PLATE

- BRONZE CDA UNS C60800 SCRAP / BRONZE CDA UNS C60800 BAR / BRONZE CDA UNS C60800 PLATE

- BRONZE CDA UNS C56000 SCRAP / BRONZE CDA UNS C56000 BAR / BRONZE CDA UNS C56000 PLATE

- BRONZE CDA UNS C55386 SCRAP / BRONZE CDA UNS C55386 BAR / BRONZE CDA UNS C55386 PLATE

- BRONZE CDA UNS C55385 SCRAP / BRONZE CDA UNS C55385 BAR / BRONZE CDA UNS C55385 PLATE

- BRONZE CDA UNS C55285 SCRAP / BRONZE CDA UNS C55285 BAR / BRONZE CDA UNS C55285 PLATE

- BRONZE CDA UNS C68000 SCRAP / BRONZE CDA UNS C68000 BAR / BRONZE CDA UNS C68000 PLATE

- BRONZE CDA UNS C67600 SCRAP / BRONZE CDA UNS C67600 BAR / BRONZE CDA UNS C67600 PLATE

- BRONZE CDA UNS C67500 SCRAP / BRONZE CDA UNS C67500 BAR / BRONZE CDA UNS C67500 PLATE

- BRONZE CDA UNS C67420 SCRAP / BRONZE CDA UNS C67420 BAR / BRONZE CDA UNS C67420 PLATE

- BRONZE CDA UNS C67400 SCRAP / BRONZE CDA UNS C67400 BAR / BRONZE CDA UNS C67400 PLATE

- BRONZE CDA UNS C67300 SCRAP / BRONZE CDA UNS C67300 BAR / BRONZE CDA UNS C67300 PLATE

- BRONZE CDA UNS C67000 SCRAP / BRONZE CDA UNS C67000 BAR / BRONZE CDA UNS C67000 PLATE

- BRONZE CDA UNS C66950 SCRAP / BRONZE CDA UNS C66950 BAR / BRONZE CDA UNS C66950 PLATE

- BRONZE CDA UNS C66930 SCRAP / BRONZE CDA UNS C66930 BAR / BRONZE CDA UNS C66930 PLATE

- BRONZE CDA UNS C66925 SCRAP / BRONZE CDA UNS C66925 BAR / BRONZE CDA UNS C66925 PLATE

- BRONZE CDA UNS C66915 SCRAP / BRONZE CDA UNS C66915 BAR / BRONZE CDA UNS C66915 PLATE

- BRONZE CDA UNS C66910 SCRAP / BRONZE CDA UNS C66910 BAR / BRONZE CDA UNS C66910 PLATE

- BRONZE CDA UNS C66908 SCRAP / BRONZE CDA UNS C66908 BAR / BRONZE CDA UNS C66908 PLATE

- BRONZE CDA UNS C66900 SCRAP / BRONZE CDA UNS C66900 BAR / BRONZE CDA UNS C66900 PLATE

- BRONZE CDA UNS C66800 SCRAP / BRONZE CDA UNS C66800 BAR / BRONZE CDA UNS C66800 PLATE

- BRONZE CDA UNS C66700 SCRAP / BRONZE CDA UNS C66700 BAR / BRONZE CDA UNS C66700 PLATE

- BRONZE CDA UNS C66430 SCRAP / BRONZE CDA UNS C66430 BAR / BRONZE CDA UNS C66430 PLATE

- BRONZE CDA UNS C66420 SCRAP / BRONZE CDA UNS C66420 BAR / BRONZE CDA UNS C66420 PLATE

- BRONZE CDA UNS C66200 SCRAP / BRONZE CDA UNS C66200 BAR / BRONZE CDA UNS C66200 PLATE

- BRONZE CDA UNS C66100 SCRAP / BRONZE CDA UNS C66100 BAR / BRONZE CDA UNS C66100 PLATE

- BRONZE CDA UNS C65600 SCRAP / BRONZE CDA UNS C65600 BAR / BRONZE CDA UNS C65600 PLATE

- BRONZE CDA UNS C65500 SCRAP / BRONZE CDA UNS C65500 BAR / BRONZE CDA UNS C65500 PLATE

- BRONZE CDA UNS C65400 SCRAP / BRONZE CDA UNS C65400 BAR / BRONZE CDA UNS C65400 PLATE

- BRONZE CDA UNS C65100 SCRAP / BRONZE CDA UNS C65100 BAR / BRONZE CDA UNS C65100 PLATE

- BRONZE CDA UNS C64900 SCRAP / BRONZE CDA UNS C64900 BAR / BRONZE CDA UNS C64900 PLATE

- BRONZE CDA UNS C64800 SCRAP / BRONZE CDA UNS C64800 BAR / BRONZE CDA UNS C64800 PLATE

- BRONZE CDA UNS C64785 SCRAP / BRONZE CDA UNS C64785 BAR / BRONZE CDA UNS C64785 PLATE

- BRONZE CDA UNS C64780 SCRAP / BRONZE CDA UNS C64780 BAR / BRONZE CDA UNS C64780 PLATE

- BRONZE CDA UNS C64775 SCRAP / BRONZE CDA UNS C64775 BAR / BRONZE CDA UNS C64775 PLATE

- BRONZE CDA UNS C64770 SCRAP / BRONZE CDA UNS C64770 BAR / BRONZE CDA UNS C64770 PLATE

- BRONZE CDA UNS C64750 SCRAP / BRONZE CDA UNS C64750 BAR / BRONZE CDA UNS C64750 PLATE

- BRONZE CDA UNS C64740 SCRAP / BRONZE CDA UNS C64740 BAR / BRONZE CDA UNS C64740 PLATE

- BRONZE CDA UNS C55283 SCRAP / BRONZE CDA UNS C55283 BAR / BRONZE CDA UNS C55283 PLATE

- BRONZE CDA UNS C55282 SCRAP / BRONZE CDA UNS C55282 BAR / BRONZE CDA UNS C55282 PLATE

- BRONZE CDA UNS C55281 SCRAP / BRONZE CDA UNS C55281 BAR / BRONZE CDA UNS C55281 PLATE

- BRONZE CDA UNS C55181 SCRAP / BRONZE CDA UNS C55181 BAR / BRONZE CDA UNS C55181 PLATE

- BRONZE CDA UNS C54400 SCRAP / BRONZE CDA UNS C54400 BAR / BRONZE CDA UNS C54400 PLATE

- BRONZE CDA UNS C53800 SCRAP / BRONZE CDA UNS C53800 BAR / BRONZE CDA UNS C53800 PLATE

- BRONZE CDA UNS C53400 SCRAP / BRONZE CDA UNS C53400 BAR / BRONZE CDA UNS C53400 PLATE

- BRONZE CDA UNS C52480 SCRAP / BRONZE CDA UNS C52480 BAR / BRONZE CDA UNS C52480 PLATE

- BRONZE CDA UNS C52400 SCRAP / BRONZE CDA UNS C52400 BAR / BRONZE CDA UNS C52400 PLATE

- BRONZE CDA UNS C52180 SCRAP / BRONZE CDA UNS C52180 BAR / BRONZE CDA UNS C52180 PLATE

- BRONZE CDA UNS C52100 SCRAP / BRONZE CDA UNS C52100 BAR / BRONZE CDA UNS C52100 PLATE

- BRONZE CDA UNS C51980 SCRAP / BRONZE CDA UNS C51980 BAR / BRONZE CDA UNS C51980 PLATE

- BRONZE CDA UNS C51900 SCRAP / BRONZE CDA UNS C51900 BAR / BRONZE CDA UNS C51900 PLATE

- BRONZE CDA UNS C51190 SCRAP / BRONZE CDA UNS C51190 BAR / BRONZE CDA UNS C51190 PLATE

- BRONZE CDA UNS C51180 SCRAP / BRONZE CDA UNS C51180 BAR / BRONZE CDA UNS C51180 PLATE

- BRONZE CDA UNS C51000 SCRAP / BRONZE CDA UNS C51000 BAR / BRONZE CDA UNS C51000 PLATE

- BRONZE CDA UNS C50900 SCRAP / BRONZE CDA UNS C50900 BAR / BRONZE CDA UNS C50900 PLATE

- BRONZE CDA UNS C50780 SCRAP / BRONZE CDA UNS C50780 BAR / BRONZE CDA UNS C50780 PLATE

- BRONZE CDA UNS C50725 SCRAP / BRONZE CDA UNS C50725 BAR / BRONZE CDA UNS C50725 PLATE

- BRONZE CDA UNS C50715 SCRAP / BRONZE CDA UNS C50715 BAR / BRONZE CDA UNS C50715 PLATE

- BRONZE CDA UNS C50710 SCRAP / BRONZE CDA UNS C50710 BAR / BRONZE CDA UNS C50710 PLATE

- BRONZE CDA UNS C50510 SCRAP / BRONZE CDA UNS C50510 BAR / BRONZE CDA UNS C50510 PLATE

- BRONZE CDA UNS C90500 SCRAP / BRONZE CDA UNS C90500 BAR / BRONZE CDA UNS C90500 PLATE

- BRONZE CDA UNS C50500 SCRAP / BRONZE CDA UNS C50500 BAR / BRONZE CDA UNS C50500 PLATE

- BRONZE CDA UNS C50100 SCRAP / BRONZE CDA UNS C50100 BAR / BRONZE CDA UNS C50100 PLATE

- BRONZE CDA UNS C90420 SCRAP / BRONZE CDA UNS C90420 BAR / BRONZE CDA UNS C90420 PLATE

- BRONZE CDA UNS C90410 SCRAP / BRONZE CDA UNS C90410 BAR / BRONZE CDA UNS C90410 PLATE

- BRONZE CDA UNS C90300 SCRAP / BRONZE CDA UNS C90300 BAR / BRONZE CDA UNS C90300 PLATE

- BRONZE CDA UNS C90200 SCRAP / BRONZE CDA UNS C90200 BAR / BRONZE CDA UNS C90200 PLATE

- BRONZE CDA UNS C69750 SCRAP / BRONZE CDA UNS C69750 BAR / BRONZE CDA UNS C69750 PLATE

- BRONZE CDA UNS C69700 SCRAP / BRONZE CDA UNS C69700 BAR / BRONZE CDA UNS C69700 PLATE

- BRONZE CDA UNS C69300 SCRAP / BRONZE CDA UNS C69300 BAR / BRONZE CDA UNS C69300 PLATE

- BRONZE CDA UNS C69250 SCRAP / BRONZE CDA UNS C69250 BAR / BRONZE CDA UNS C69250 PLATE

- BRONZE CDA UNS C69220 SCRAP / BRONZE CDA UNS C69220 BAR / BRONZE CDA UNS C69220 PLATE

- BRONZE CDA UNS C69100 SCRAP / BRONZE CDA UNS C69100 BAR / BRONZE CDA UNS C69100 PLATE

- BRONZE CDA UNS C69050 SCRAP / BRONZE CDA UNS C69050 BAR / BRONZE CDA UNS C69050 PLATE

- BRONZE CDA UNS C64728 SCRAP / BRONZE CDA UNS C64728 BAR / BRONZE CDA UNS C64728 PLATE

- BRONZE CDA UNS C64727 SCRAP / BRONZE CDA UNS C64727 BAR / BRONZE CDA UNS C64727 PLATE

- BRONZE CDA UNS C64725 SCRAP / BRONZE CDA UNS C64725 BAR / BRONZE CDA UNS C64725 PLATE

- BRONZE CDA UNS C69400 SCRAP / BRONZE CDA UNS C69400 BAR / BRONZE CDA UNS C69400 PLATE

- BRONZE CDA UNS C64710 SCRAP / BRONZE CDA UNS C64710 BAR / BRONZE CDA UNS C64710 PLATE

- BRONZE CDA UNS C68800 SCRAP / BRONZE CDA UNS C68800 BAR / BRONZE CDA UNS C68800 PLATE

- BRONZE CDA UNS C68700 SCRAP / BRONZE CDA UNS C68700 BAR / BRONZE CDA UNS C68700 PLATE

- BRONZE CDA UNS C68600 SCRAP / BRONZE CDA UNS C68600 BAR / BRONZE CDA UNS C68600 PLATE

- BRONZE CDA UNS C68350 SCRAP / BRONZE CDA UNS C68350 BAR / BRONZE CDA UNS C68350 PLATE

- BRONZE CDA UNS C68300 SCRAP / BRONZE CDA UNS C68300 BAR / BRONZE CDA UNS C68300 PLATE

- BRONZE CDA UNS C99750 SCRAP / BRONZE CDA UNS C99750 BAR / BRONZE CDA UNS C99750 PLATE

- BRONZE CDA UNS C99740 SCRAP / BRONZE CDA UNS C99740 BAR / BRONZE CDA UNS C99740 PLATE

- BRONZE CDA UNS C99710 SCRAP / BRONZE CDA UNS C99710 BAR / BRONZE CDA UNS C99710 PLATE

- BRONZE CDA UNS C99700 SCRAP / BRONZE CDA UNS C99700 BAR / BRONZE CDA UNS C99700 PLATE

- BRONZE CDA UNS C99600 SCRAP / BRONZE CDA UNS C99600 BAR / BRONZE CDA UNS C99600 PLATE

- BRONZE CDA UNS C94700 SCRAP / BRONZE CDA UNS C94700 BAR / BRONZE CDA UNS C94700 PLATE

- BRONZE CDA UNS C94500 SCRAP / BRONZE CDA UNS C94500 BAR / BRONZE CDA UNS C94500 PLATE

- BRONZE CDA UNS C94400 SCRAP / BRONZE CDA UNS C94400 BAR / BRONZE CDA UNS C94400 PLATE

- BRONZE CDA UNS C94320 SCRAP / BRONZE CDA UNS C94320 BAR / BRONZE CDA UNS C94320 PLATE

- BRONZE CDA UNS C94310 SCRAP / BRONZE CDA UNS C94310 BAR / BRONZE CDA UNS C94310 PLATE

- BRONZE CDA UNS C94300 SCRAP / BRONZE CDA UNS C94300 BAR / BRONZE CDA UNS C94300 PLATE

- BRONZE CDA UNS C94100 SCRAP / BRONZE CDA UNS C94100 BAR / BRONZE CDA UNS C94100 PLATE

- BRONZE CDA UNS C94000 SCRAP / BRONZE CDA UNS C94000 BAR / BRONZE CDA UNS C94000 PLATE

- BRONZE CDA UNS C93900 SCRAP / BRONZE CDA UNS C93900 BAR / BRONZE CDA UNS C93900 PLATE

- BRONZE CDA UNS C93800 SCRAP / BRONZE CDA UNS C93800 BAR / BRONZE CDA UNS C93800 PLATE

- BRONZE CDA UNS C93720 SCRAP / BRONZE CDA UNS C93720 BAR / BRONZE CDA UNS C93720 PLATE

- BRONZE CDA UNS C93700 SCRAP / BRONZE CDA UNS C93700 BAR / BRONZE CDA UNS C93700 PLATE

- BRONZE CDA UNS C93600 SCRAP / BRONZE CDA UNS C93600 BAR / BRONZE CDA UNS C93600 PLATE

- BRONZE CDA UNS C93500 SCRAP / BRONZE CDA UNS C93500 BAR / BRONZE CDA UNS C93500 PLATE

- BRONZE CDA UNS C93400 SCRAP / BRONZE CDA UNS C93400 BAR / BRONZE CDA UNS C93400 PLATE

- BRONZE CDA UNS C93200 SCRAP / BRONZE CDA UNS C93200 BAR / BRONZE CDA UNS C93200 PLATE

- BRONZE CDA UNS C93100 SCRAP / BRONZE CDA UNS C93100 BAR / BRONZE CDA UNS C93100 PLATE

- BRONZE CDA UNS C92900 SCRAP / BRONZE CDA UNS C92900 BAR / BRONZE CDA UNS C92900 PLATE

- BRONZE CDA UNS C92800 SCRAP / BRONZE CDA UNS C92800 BAR / BRONZE CDA UNS C92800 PLATE

- BRONZE CDA UNS C64210 SCRAP / BRONZE CDA UNS C64210 BAR / BRONZE CDA UNS C64210 PLATE

- BRONZE CDA UNS C64200 SCRAP / BRONZE CDA UNS C64200 BAR / BRONZE CDA UNS C64200 PLATE

- BRONZE CDA UNS C92710 SCRAP / BRONZE CDA UNS C92710 BAR / BRONZE CDA UNS C92710 PLATE

- BRONZE CDA UNS C63800 SCRAP / BRONZE CDA UNS C63800 BAR / BRONZE CDA UNS C63800 PLATE

- BRONZE CDA UNS C63600 SCRAP / BRONZE CDA UNS C63600 BAR / BRONZE CDA UNS C63600 PLATE

- BRONZE CDA UNS C92700 SCRAP / BRONZE CDA UNS C92700 BAR / BRONZE CDA UNS C92700 PLATE

- BRONZE CDA UNS C63500 SCRAP / BRONZE CDA UNS C63500 BAR / BRONZE CDA UNS C63500 PLATE

- BRONZE CDA UNS C92610 SCRAP / BRONZE CDA UNS C92610 BAR / BRONZE CDA UNS C92610 PLATE

- BRONZE CDA UNS C92600 SCRAP / BRONZE CDA UNS C92600 BAR / BRONZE CDA UNS C92600 PLATE

- BRONZE CDA UNS C92500 SCRAP / BRONZE CDA UNS C92500 BAR / BRONZE CDA UNS C92500 PLATE

- BRONZE CDA UNS C92410 SCRAP / BRONZE CDA UNS C92410 BAR / BRONZE CDA UNS C92410 PLATE

- BRONZE CDA UNS C92300 SCRAP / BRONZE CDA UNS C92300 BAR / BRONZE CDA UNS C92300 PLATE

- BRONZE CDA UNS C90800 SCRAP / BRONZE CDA UNS C90800 BAR / BRONZE CDA UNS C90800 PLATE

- BRONZE CDA UNS C92220 SCRAP / BRONZE CDA UNS C92220 BAR / BRONZE CDA UNS C92220 PLATE

- BRONZE CDA UNS C92210 SCRAP / BRONZE CDA UNS C92210 BAR / BRONZE CDA UNS C92210 PLATE

- BRONZE CDA UNS C90710 SCRAP / BRONZE CDA UNS C90710 BAR / BRONZE CDA UNS C90710 PLATE

- BRONZE CDA UNS C92200 SCRAP / BRONZE CDA UNS C92200 BAR / BRONZE CDA UNS C92200 PLATE

- BRONZE CDA UNS C91700 SCRAP / BRONZE CDA UNS C91700 BAR / BRONZE CDA UNS C91700 PLATE

- BRONZE CDA UNS C91600 SCRAP / BRONZE CDA UNS C91600 BAR / BRONZE CDA UNS C91600 PLATE

- BRONZE CDA UNS C91300 SCRAP / BRONZE CDA UNS C91300 BAR / BRONZE CDA UNS C91300 PLATE

- BRONZE CDA UNS C91100 SCRAP / BRONZE CDA UNS C91100 BAR / BRONZE CDA UNS C91100 PLATE

- BRONZE CDA UNS C91000 SCRAP / BRONZE CDA UNS C91000 BAR / BRONZE CDA UNS C91000 PLATE

- BRONZE CDA UNS C90810 SCRAP / BRONZE CDA UNS C90810 BAR / BRONZE CDA UNS C90810 PLATE

- BRONZE CDA UNS C90700 SCRAP / BRONZE CDA UNS C90700 BAR / BRONZE CDA UNS C90700 PLATE

- BRONZE CDA UNS C90430 SCRAP / BRONZE CDA UNS C90430 BAR / BRONZE CDA UNS C90430 PLATE

- BRONZE CDA UNS C69710 SCRAP / BRONZE CDA UNS C69710 BAR / BRONZE CDA UNS C69710 PLATE

- BRONZE CDA UNS C69430 SCRAP / BRONZE CDA UNS C69430 BAR / BRONZE CDA UNS C69430 PLATE

- BRONZE CDA UNS C66913 SCRAP / BRONZE CDA UNS C66913 BAR / BRONZE CDA UNS C66913 PLATE

- BRONZE CDA UNS C66410 SCRAP / BRONZE CDA UNS C66410 BAR / BRONZE CDA UNS C66410 PLATE

- BRONZE CDA UNS C66400 SCRAP / BRONZE CDA UNS C66400 BAR / BRONZE CDA UNS C66400 PLATE

- BRONZE CDA UNS C66300 SCRAP / BRONZE CDA UNS C66300 BAR / BRONZE CDA UNS C66300 PLATE

- BRONZE CDA UNS C64760 SCRAP / BRONZE CDA UNS C64760 BAR / BRONZE CDA UNS C64760 PLATE

- BRONZE CDA UNS C50705 SCRAP / BRONZE CDA UNS C50705 BAR / BRONZE CDA UNS C50705 PLATE

- BRONZE CDA UNS C62582 SCRAP / BRONZE CDA UNS C62582 BAR / BRONZE CDA UNS C62582 PLATE

- BRONZE CDA UNS C55280 SCRAP / BRONZE CDA UNS C55280 BAR / BRONZE CDA UNS C55280 PLATE

- BRONZE CDA UNS C55180 SCRAP / BRONZE CDA UNS C55180 BAR / BRONZE CDA UNS C55180 PLATE

- BRONZE CDA UNS C51080 SCRAP / BRONZE CDA UNS C51080 BAR / BRONZE CDA UNS C51080 PLATE

- BRONZE CDA UNS C51800 SCRAP / BRONZE CDA UNS C51800 BAR / BRONZE CDA UNS C51800 PLATE

- BRONZE CDA UNS C51100 SCRAP / BRONZE CDA UNS C51100 BAR / BRONZE CDA UNS C51100 PLATE

- BRONZE CDA UNS C50590 SCRAP / BRONZE CDA UNS C50590 BAR / BRONZE CDA UNS C50590 PLATE

- BRONZE CDA UNS C50200 SCRAP / BRONZE CDA UNS C50200 BAR / BRONZE CDA UNS C50200 PLATE

- BRONZE CDA UNS C50150 SCRAP / BRONZE CDA UNS C50150 BAR / BRONZE CDA UNS C50150 PLATE

- ALUMINIUM BRONZE BS 2874 CA 104 SCRAP / ALUMINIUM BRONZE BS 2874 CA 104 BAR / ALUMINIUM BRONZE BS 2874 CA 104 PLATE

- BRONZE CDA UNS C94330 SCRAP / BRONZE CDA UNS C94330 BAR / BRONZE CDA UNS C94330 PLATE

- BRONZE CDA UNS C98800 SCRAP / BRONZE CDA UNS C98800 BAR / BRONZE CDA UNS C98800 PLATE

- BRONZE CDA UNS C99300 SCRAP / BRONZE CDA UNS C99300 BAR / BRONZE CDA UNS C99300 PLATE

- BRONZE CDA UNS C92810 SCRAP / BRONZE CDA UNS C92810 BAR / BRONZE CDA UNS C92810 PLATE

- BRONZE CDA UNS C92310 SCRAP / BRONZE CDA UNS C92310 BAR / BRONZE CDA UNS C92310 PLATE

- BRONZE CDA UNS C64790 SCRAP / BRONZE CDA UNS C64790 BAR / BRONZE CDA UNS C64790 PLATE

- Copper Scrap

- COPPER CDA UNS C18660 SCRAP / COPPER CDA UNS C18660 BAR / COPPER CDA UNS C18660 PLATE

- COPPER CDA UNS C17530 SCRAP / COPPER CDA UNS C17530 BAR / COPPER CDA UNS C17530 PLATE

- COPPER CDA UNS C18600 SCRAP / COPPER CDA UNS C18600 BAR / COPPER CDA UNS C18600 PLATE

- COPPER CDA UNS C17460 SCRAP / COPPER CDA UNS C17460 BAR / COPPER CDA UNS C17460 PLATE

- COPPER CDA UNS C82400 SCRAP / COPPER CDA UNS C82400 BAR / COPPER CDA UNS C82400 PLATE

- COPPER CDA UNS C82800 SCRAP / COPPER CDA UNS C82800 BAR / COPPER CDA UNS C82800 PLATE

- COPPER CDA UNS C82600 SCRAP / COPPER CDA UNS C82600 BAR / COPPER CDA UNS C82600 PLATE

- COPPER CDA UNS C14180 SCRAP / COPPER CDA UNS C14180 BAR / COPPER CDA UNS C14180 PLATE

- COPPER CDA UNS C14420 SCRAP / COPPER CDA UNS C14420 BAR / COPPER CDA UNS C14420 PLATE

- COPPER CDA UNS C18900 SCRAP / COPPER CDA UNS C18900 BAR / COPPER CDA UNS C18900 PLATE

- COPPER CDA UNS C15900 SCRAP / COPPER CDA UNS C15900 BAR / COPPER CDA UNS C15900 PLATE

- COPPER CDA UNS C15815 SCRAP / COPPER CDA UNS C15815 BAR / COPPER CDA UNS C15815 PLATE

- COPPER CDA UNS C19700 SCRAP / COPPER CDA UNS C19700 BAR / COPPER CDA UNS C19700 PLATE

- COPPER CDA UNS C19800 SCRAP / COPPER CDA UNS C19800 BAR / COPPER CDA UNS C19800 PLATE

- COPPER CDA UNS C19500 SCRAP / COPPER CDA UNS C19500 BAR / COPPER CDA UNS C19500 PLATE

- COPPER CDA UNS C19220 SCRAP / COPPER CDA UNS C19220 BAR / COPPER CDA UNS C19220 PLATE

- COPPER CDA UNS C19030 SCRAP / COPPER CDA UNS C19030 BAR / COPPER CDA UNS C19030 PLATE

- COPPER CDA UNS C18070 SCRAP / COPPER CDA UNS C18070 BAR / COPPER CDA UNS C18070 PLATE

- COPPER CDA UNS C18100 SCRAP / COPPER CDA UNS C18100 BAR / COPPER CDA UNS C18100 PLATE

- COPPER CDA UNS C18080 SCRAP / COPPER CDA UNS C18080 BAR / COPPER CDA UNS C18080 PLATE

- COPPER CDA UNS C18835 SCRAP / COPPER CDA UNS C18835 BAR / COPPER CDA UNS C18835 PLATE

- COPPER CDA UNS C18020 SCRAP / COPPER CDA UNS C18020 BAR / COPPER CDA UNS C18020 PLATE

- COPPER CDA UNS C18000 SCRAP / COPPER CDA UNS C18000 BAR / COPPER CDA UNS C18000 PLATE

- COPPER CDA UNS C17510 SCRAP / COPPER CDA UNS C17510 BAR / COPPER CDA UNS C17510 PLATE

- COPPER CDA UNS C15720 SCRAP / COPPER CDA UNS C15720 BAR / COPPER CDA UNS C15720 PLATE

- COPPER CDA UNS C15715 SCRAP / COPPER CDA UNS C15715 BAR / COPPER CDA UNS C15715 PLATE

- COPPER CDA UNS C14181 SCRAP / COPPER CDA UNS C14181 BAR / COPPER CDA UNS C14181 PLATE

- COPPER CDA UNS C81540 SCRAP / COPPER CDA UNS C81540 BAR / COPPER CDA UNS C81540 PLATE

- COPPER CDA UNS C81400 SCRAP / COPPER CDA UNS C81400 BAR / COPPER CDA UNS C81400 PLATE

- COPPER CDA UNS C80100 SCRAP / COPPER CDA UNS C80100 BAR / COPPER CDA UNS C80100 PLATE

- COPPER CDA UNS C15760 SCRAP / COPPER CDA UNS C15760 BAR / COPPER CDA UNS C15760 PLATE

- COPPER CDA UNS C11700 SCRAP / COPPER CDA UNS C11700 BAR / COPPER CDA UNS C11700 PLATE

- COPPER CDA UNS C18025 SCRAP / COPPER CDA UNS C18025 BAR / COPPER CDA UNS C18025 PLATE

- COPPER CDA UNS C11040 SCRAP / COPPER CDA UNS C11040 BAR / COPPER CDA UNS C11040 PLATE

- COPPER CDA UNS C19150 SCRAP / COPPER CDA UNS C19150 BAR / COPPER CDA UNS C19150 PLATE

- COPPER CDA UNS C17500 SCRAP / COPPER CDA UNS C17500 BAR / COPPER CDA UNS C17500 PLATE

- COPPER CDA UNS C19280 SCRAP / COPPER CDA UNS C19280 BAR / COPPER CDA UNS C19280 PLATE

- COPPER CDA UNS C19100 SCRAP / COPPER CDA UNS C19100 BAR / COPPER CDA UNS C19100 PLATE

- COPPER CDA UNS C17300 SCRAP / COPPER CDA UNS C17300 BAR / COPPER CDA UNS C17300 PLATE

- COPPER CDA UNS C18980 SCRAP / COPPER CDA UNS C18980 BAR / COPPER CDA UNS C18980 PLATE

- COPPER CDA UNS C18040 SCRAP / COPPER CDA UNS C18040 BAR / COPPER CDA UNS C18040 PLATE

- COPPER CDA UNS C80410 SCRAP / COPPER CDA UNS C80410 BAR / COPPER CDA UNS C80410 PLATE

- COPPER CDA UNS C19240 SCRAP / COPPER CDA UNS C19240 BAR / COPPER CDA UNS C19240 PLATE

- COPPER CDA UNS C18141 SCRAP / COPPER CDA UNS C18141 BAR / COPPER CDA UNS C18141 PLATE

- COPPER CDA UNS C19400 SCRAP / COPPER CDA UNS C19400 BAR / COPPER CDA UNS C19400 PLATE

- COPPER CDA UNS C19022 SCRAP / COPPER CDA UNS C19022 BAR / COPPER CDA UNS C19022 PLATE

- COPPER CDA UNS C19900 SCRAP / COPPER CDA UNS C19900 BAR / COPPER CDA UNS C19900 PLATE

- COPPER CDA UNS C19000 SCRAP / COPPER CDA UNS C19000 BAR / COPPER CDA UNS C19000 PLATE

- COPPER CDA UNS C18665 SCRAP / COPPER CDA UNS C18665 BAR / COPPER CDA UNS C18665 PLATE

- COPPER CDA UNS C15790 SCRAP / COPPER CDA UNS C15790 BAR / COPPER CDA UNS C15790 PLATE

- COPPER CDA UNS C18661 SCRAP / COPPER CDA UNS C18661 BAR / COPPER CDA UNS C18661 PLATE

- COPPER CDA UNS C18610 SCRAP / COPPER CDA UNS C18610 BAR / COPPER CDA UNS C18610 PLATE

- COPPER CDA UNS C81200 SCRAP / COPPER CDA UNS C81200 BAR / COPPER CDA UNS C81200 PLATE

- COPPER CDA UNS C19002 SCRAP / COPPER CDA UNS C19002 BAR / COPPER CDA UNS C19002 PLATE

- COPPER CDA UNS C18140 SCRAP / COPPER CDA UNS C18140 BAR / COPPER CDA UNS C18140 PLATE

- COPPER CDA UNS C18620 SCRAP / COPPER CDA UNS C18620 BAR / COPPER CDA UNS C18620 PLATE

- COPPER CDA UNS C18200 SCRAP / COPPER CDA UNS C18200 BAR / COPPER CDA UNS C18200 PLATE

- COPPER CDA UNS C19025 SCRAP / COPPER CDA UNS C19025 BAR / COPPER CDA UNS C19025 PLATE

- COPPER CDA UNS C19020 SCRAP / COPPER CDA UNS C19020 BAR / COPPER CDA UNS C19020 PLATE

- COPPER CDA UNS C17455 SCRAP / COPPER CDA UNS C17455 BAR / COPPER CDA UNS C17455 PLATE

- COPPER CDA UNS C18150 SCRAP / COPPER CDA UNS C18150 BAR / COPPER CDA UNS C18150 PLATE

- COPPER CDA UNS C18700 SCRAP / COPPER CDA UNS C18700 BAR / COPPER CDA UNS C18700 PLATE

- COPPER CDA UNS C19050 SCRAP / COPPER CDA UNS C19050 BAR / COPPER CDA UNS C19050 PLATE

- COPPER CDA UNS C18400 SCRAP / COPPER CDA UNS C18400 BAR / COPPER CDA UNS C18400 PLATE

- COPPER CDA UNS C16500 SCRAP / COPPER CDA UNS C16500 BAR / COPPER CDA UNS C16500 PLATE

- COPPER CDA UNS C18990 SCRAP / COPPER CDA UNS C18990 BAR / COPPER CDA UNS C18990 PLATE

- COPPER CDA UNS C18143 SCRAP / COPPER CDA UNS C18143 BAR / COPPER CDA UNS C18143 PLATE

- COPPER CDA UNS C82500 SCRAP / COPPER CDA UNS C82500 BAR / COPPER CDA UNS C82500 PLATE

- COPPER CDA UNS C12300 SCRAP / COPPER CDA UNS C12300 BAR / COPPER CDA UNS C12300 PLATE

- COPPER CDA UNS C81100 SCRAP / COPPER CDA UNS C81100 BAR / COPPER CDA UNS C81100 PLATE

- COPPER CDA UNS C12500 SCRAP / COPPER CDA UNS C12500 BAR / COPPER CDA UNS C12500 PLATE

- COPPER CDA UNS C12900 SCRAP / COPPER CDA UNS C12900 BAR / COPPER CDA UNS C12900 PLATE

- COPPER CDA UNS C15500 SCRAP / COPPER CDA UNS C15500 BAR / COPPER CDA UNS C15500 PLATE

- COPPER CDA UNS C13100 SCRAP / COPPER CDA UNS C13100 BAR / COPPER CDA UNS C13100 PLATE

- COPPER CDA UNS C14200 SCRAP / COPPER CDA UNS C14200 BAR / COPPER CDA UNS C14200 PLATE

- COPPER CDA UNS C17465 SCRAP / COPPER CDA UNS C17465 BAR / COPPER CDA UNS C17465 PLATE

- COPPER CDA UNS C82000 SCRAP / COPPER CDA UNS C82000 BAR / COPPER CDA UNS C82000 PLATE

- COPPER CDA UNS C15780 SCRAP / COPPER CDA UNS C15780 BAR / COPPER CDA UNS C15780 PLATE

- COPPER CDA UNS C13150 SCRAP / COPPER CDA UNS C13150 BAR / COPPER CDA UNS C13150 PLATE

- COPPER CDA UNS C17200 SCRAP / COPPER CDA UNS C17200 BAR / COPPER CDA UNS C17200 PLATE

- COPPER CDA UNS C14415 SCRAP / COPPER CDA UNS C14415 BAR / COPPER CDA UNS C14415 PLATE

- COPPER CDA UNS C12510 SCRAP / COPPER CDA UNS C12510 BAR / COPPER CDA UNS C12510 PLATE

- COPPER CDA UNS C15150 SCRAP / COPPER CDA UNS C15150 BAR / COPPER CDA UNS C15150 PLATE

- COPPER CDA UNS C15000 SCRAP / COPPER CDA UNS C15000 BAR / COPPER CDA UNS C15000 PLATE

- COPPER CDA UNS C82700 SCRAP / COPPER CDA UNS C82700 BAR / COPPER CDA UNS C82700 PLATE

- COPPER CDA UNS C14530 SCRAP / COPPER CDA UNS C14530 BAR / COPPER CDA UNS C14530 PLATE

- COPPER CDA UNS C17450 SCRAP / COPPER CDA UNS C17450 BAR / COPPER CDA UNS C17450 PLATE

- COPPER CDA UNS C17410 SCRAP / COPPER CDA UNS C17410 BAR / COPPER CDA UNS C17410 PLATE

- COPPER CDA UNS C81500 SCRAP / COPPER CDA UNS C81500 BAR / COPPER CDA UNS C81500 PLATE

- COPPER CDA UNS C14520 SCRAP / COPPER CDA UNS C14520 BAR / COPPER CDA UNS C14520 PLATE

- COPPER CDA UNS C15750 SCRAP / COPPER CDA UNS C15750 BAR / COPPER CDA UNS C15750 PLATE

- COPPER CDA UNS C18045 SCRAP / COPPER CDA UNS C18045 BAR / COPPER CDA UNS C18045 PLATE

- COPPER CDA UNS C18030 SCRAP / COPPER CDA UNS C18030 BAR / COPPER CDA UNS C18030 PLATE

- COPPER CDA UNS C12210 SCRAP / COPPER CDA UNS C12210 BAR / COPPER CDA UNS C12210 PLATE

- COPPER CDA UNS C15730 SCRAP / COPPER CDA UNS C15730 BAR / COPPER CDA UNS C15730 PLATE

- COPPER CDA UNS C14700 SCRAP / COPPER CDA UNS C14700 BAR / COPPER CDA UNS C14700 PLATE

- COPPER CDA UNS C14500 SCRAP / COPPER CDA UNS C14500 BAR / COPPER CDA UNS C14500 PLATE

- COPPER CDA UNS C14510 SCRAP / COPPER CDA UNS C14510 BAR / COPPER CDA UNS C14510 PLATE

- COPPER CDA UNS C14750 SCRAP / COPPER CDA UNS C14750 BAR / COPPER CDA UNS C14750 PLATE

- COPPER CDA UNS C14425 SCRAP / COPPER CDA UNS C14425 BAR / COPPER CDA UNS C14425 PLATE

- COPPER CDA UNS C14410 SCRAP / COPPER CDA UNS C14410 BAR / COPPER CDA UNS C14410 PLATE

- COPPER CDA UNS C12100 SCRAP / COPPER CDA UNS C12100 BAR / COPPER CDA UNS C12100 PLATE

- COPPER CDA UNS C11500 SCRAP / COPPER CDA UNS C11500 BAR / COPPER CDA UNS C11500 PLATE

- COPPER CDA UNS C12200 SCRAP / COPPER CDA UNS C12200 BAR / COPPER CDA UNS C12200 PLATE

- COPPER CDA UNS C10500 SCRAP / COPPER CDA UNS C10500 BAR / COPPER CDA UNS C10500 PLATE

- COPPER CDA UNS C15650 SCRAP / COPPER CDA UNS C15650 BAR / COPPER CDA UNS C15650 PLATE

- COPPER CDA UNS C11300 SCRAP / COPPER CDA UNS C11300 BAR / COPPER CDA UNS C11300 PLATE

- COPPER CDA UNS C10200 SCRAP / COPPER CDA UNS C10200 BAR / COPPER CDA UNS C10200 PLATE

- COPPER CDA UNS C11030 SCRAP / COPPER CDA UNS C11030 BAR / COPPER CDA UNS C11030 PLATE

- COPPER CDA UNS C11020 SCRAP / COPPER CDA UNS C11020 BAR / COPPER CDA UNS C11020 PLATE

- COPPER CDA UNS C11010 SCRAP / COPPER CDA UNS C11010 BAR / COPPER CDA UNS C11010 PLATE

- COPPER CDA UNS C11000 SCRAP / COPPER CDA UNS C11000 BAR / COPPER CDA UNS C11000 PLATE

- COPPER CDA UNS C10940 SCRAP / COPPER CDA UNS C10940 BAR / COPPER CDA UNS C10940 PLATE

- COPPER CDA UNS C10930 SCRAP / COPPER CDA UNS C10930 BAR / COPPER CDA UNS C10930 PLATE

- COPPER CDA UNS C10920 SCRAP / COPPER CDA UNS C10920 BAR / COPPER CDA UNS C10920 PLATE

- COPPER CDA UNS C10700 SCRAP / COPPER CDA UNS C10700 BAR / COPPER CDA UNS C10700 PLATE

- COPPER CDA UNS C10910 SCRAP / COPPER CDA UNS C10910 BAR / COPPER CDA UNS C10910 PLATE

- COPPER CDA UNS C10800 SCRAP / COPPER CDA UNS C10800 BAR / COPPER CDA UNS C10800 PLATE

- COPPER CDA UNS C10400 SCRAP / COPPER CDA UNS C10400 BAR / COPPER CDA UNS C10400 PLATE

- COPPER CDA UNS C10300 SCRAP / COPPER CDA UNS C10300 BAR / COPPER CDA UNS C10300 PLATE

- COPPER CDA UNS C10100 SCRAP / COPPER CDA UNS C10100 BAR / COPPER CDA UNS C10100 PLATE

- COPPER CDA UNS C19750 SCRAP / COPPER CDA UNS C19750 BAR / COPPER CDA UNS C19750 PLATE

- COPPER CDA UNS C19810 SCRAP / COPPER CDA UNS C19810 BAR / COPPER CDA UNS C19810 PLATE

- COPPER CDA UNS C19720 SCRAP / COPPER CDA UNS C19720 BAR / COPPER CDA UNS C19720 PLATE

- COPPER CDA UNS C19419 SCRAP / COPPER CDA UNS C19419 BAR / COPPER CDA UNS C19419 PLATE

- COPPER CDA UNS C19015 SCRAP / COPPER CDA UNS C19015 BAR / COPPER CDA UNS C19015 PLATE

- COPPER CDA UNS C19010 SCRAP / COPPER CDA UNS C19010 BAR / COPPER CDA UNS C19010 PLATE

- COPPER CDA UNS C19027 SCRAP / COPPER CDA UNS C19027 BAR / COPPER CDA UNS C19027 PLATE

- COPPER CDA UNS C19215 SCRAP / COPPER CDA UNS C19215 BAR / COPPER CDA UNS C19215 PLATE

- COPPER CDA UNS C19710 SCRAP / COPPER CDA UNS C19710 BAR / COPPER CDA UNS C19710 PLATE

- COPPER CDA UNS C19260 SCRAP / COPPER CDA UNS C19260 BAR / COPPER CDA UNS C19260 PLATE

- COPPER CDA UNS C19250 SCRAP / COPPER CDA UNS C19250 BAR / COPPER CDA UNS C19250 PLATE

- COPPER CDA UNS C19200 SCRAP / COPPER CDA UNS C19200 BAR / COPPER CDA UNS C19200 PLATE

- COPPER CDA UNS C19450 SCRAP / COPPER CDA UNS C19450 BAR / COPPER CDA UNS C19450 PLATE

- COPPER CDA UNS C19210 SCRAP / COPPER CDA UNS C19210 BAR / COPPER CDA UNS C19210 PLATE

- COPPER CDA UNS C19024 SCRAP / COPPER CDA UNS C19024 BAR / COPPER CDA UNS C19024 PLATE

- COPPER CDA UNS C19170 SCRAP / COPPER CDA UNS C19170 BAR / COPPER CDA UNS C19170 PLATE

- COPPER CDA UNS C19410 SCRAP / COPPER CDA UNS C19410 BAR / COPPER CDA UNS C19410 PLATE

- COPPER CDA UNS C19140 SCRAP / COPPER CDA UNS C19140 BAR / COPPER CDA UNS C19140 PLATE

- COPPER CDA UNS C19040 SCRAP / COPPER CDA UNS C19040 BAR / COPPER CDA UNS C19040 PLATE

- COPPER CDA UNS C11600 SCRAP / COPPER CDA UNS C11600 BAR / COPPER CDA UNS C11600 PLATE

- COPPER CDA UNS C12000 SCRAP / COPPER CDA UNS C12000 BAR / COPPER CDA UNS C12000 PLATE

- COPPER CDA UNS C12220 SCRAP / COPPER CDA UNS C12220 BAR / COPPER CDA UNS C12220 PLATE

- COPPER CDA UNS C14300 SCRAP / COPPER CDA UNS C14300 BAR / COPPER CDA UNS C14300 PLATE

- COPPER CDA UNS C16200 SCRAP / COPPER CDA UNS C16200 BAR / COPPER CDA UNS C16200 PLATE

- COPPER CDA UNS C15100 SCRAP / COPPER CDA UNS C15100 BAR / COPPER CDA UNS C15100 PLATE

- COPPER CDA UNS C15725 SCRAP / COPPER CDA UNS C15725 BAR / COPPER CDA UNS C15725 PLATE

- COPPER CDA UNS C82510 SCRAP / COPPER CDA UNS C82510 BAR / COPPER CDA UNS C82510 PLATE

- COPPER CDA UNS C18050 SCRAP / COPPER CDA UNS C18050 BAR / COPPER CDA UNS C18050 PLATE

- COPPER CDA UNS C18090 SCRAP / COPPER CDA UNS C18090 BAR / COPPER CDA UNS C18090 PLATE

- COPPER CDA UNS C18135 SCRAP / COPPER CDA UNS C18135 BAR / COPPER CDA UNS C18135 PLATE

- COPPER CDA UNS C18145 SCRAP / COPPER CDA UNS C18145 BAR / COPPER CDA UNS C18145 PLATE

- COPPER CDA UNS C19160 SCRAP / COPPER CDA UNS C19160 BAR / COPPER CDA UNS C19160 PLATE

- COPPER CDA UNS C19520 SCRAP / COPPER CDA UNS C19520 BAR / COPPER CDA UNS C19520 PLATE

- COPPER CDA UNS C82200 SCRAP / COPPER CDA UNS C82200 BAR / COPPER CDA UNS C82200 PLATE

- COPPER CDA UNS C17000 SCRAP / COPPER CDA UNS C17000 BAR / COPPER CDA UNS C17000 PLATE

- COPPER CDA UNS C11400 SCRAP / COPPER CDA UNS C11400 BAR / COPPER CDA UNS C11400 PLATE

- COPPER CDA UNS C11100 SCRAP / COPPER CDA UNS C11100 BAR / COPPER CDA UNS C11100 PLATE

- COPPER CDA UNS C11045 SCRAP / COPPER CDA UNS C11045 BAR / COPPER CDA UNS C11045 PLATE

- Nickel Silver Scrap

- NICKEL SILVER CDA UNS C77300 SCRAP / NICKEL SILVER CDA UNS C77300 BAR / NICKEL SILVER CDA UNS C77300 PLATE

- NICKEL SILVER CDA UNS C74000 SCRAP / NICKEL SILVER CDA UNS C74000 BAR / NICKEL SILVER CDA UNS C74000 PLATE

- NICKEL SILVER CDA UNS C74400 SCRAP / NICKEL SILVER CDA UNS C74400 BAR / NICKEL SILVER CDA UNS C74400 PLATE

- NICKEL SILVER CDA UNS C73500 SCRAP / NICKEL SILVER CDA UNS C73500 BAR / NICKEL SILVER CDA UNS C73500 PLATE

- NICKEL SILVER CDA UNS C74300 SCRAP / NICKEL SILVER CDA UNS C74300 BAR / NICKEL SILVER CDA UNS C74300 PLATE

- NICKEL SILVER CDA UNS C97600 SCRAP / NICKEL SILVER CDA UNS C97600 BAR / NICKEL SILVER CDA UNS C97600 PLATE

- NICKEL SILVER CDA UNS C79200 SCRAP / NICKEL SILVER CDA UNS C79200 BAR / NICKEL SILVER CDA UNS C79200 PLATE

- NICKEL SILVER CDA UNS C79350 SCRAP / NICKEL SILVER CDA UNS C79350 BAR / NICKEL SILVER CDA UNS C79350 PLATE

- NICKEL SILVER CDA UNS C79600 SCRAP / NICKEL SILVER CDA UNS C79600 BAR / NICKEL SILVER CDA UNS C79600 PLATE

- NICKEL SILVER CDA UNS C74500 SCRAP / NICKEL SILVER CDA UNS C74500 BAR / NICKEL SILVER CDA UNS C74500 PLATE

- NICKEL SILVER CDA UNS C79830 SCRAP / NICKEL SILVER CDA UNS C79830 BAR / NICKEL SILVER CDA UNS C79830 PLATE

- NICKEL SILVER CDA UNS C79860 SCRAP / NICKEL SILVER CDA UNS C79860 BAR / NICKEL SILVER CDA UNS C79860 PLATE

- NICKEL SILVER CDA UNS C75200 SCRAP / NICKEL SILVER CDA UNS C75200 BAR / NICKEL SILVER CDA UNS C75200 PLATE

- NICKEL SILVER CDA UNS C75400 SCRAP / NICKEL SILVER CDA UNS C75400 BAR / NICKEL SILVER CDA UNS C75400 PLATE

- NICKEL SILVER CDA UNS C75700 SCRAP / NICKEL SILVER CDA UNS C75700 BAR / NICKEL SILVER CDA UNS C75700 PLATE

- NICKEL SILVER CDA UNS C76000 SCRAP / NICKEL SILVER CDA UNS C76000 BAR / NICKEL SILVER CDA UNS C76000 PLATE

- NICKEL SILVER CDA UNS C76200 SCRAP / NICKEL SILVER CDA UNS C76200 BAR / NICKEL SILVER CDA UNS C76200 PLATE

- NICKEL SILVER CDA UNS C76400 SCRAP / NICKEL SILVER CDA UNS C76400 BAR / NICKEL SILVER CDA UNS C76400 PLATE

- NICKEL SILVER CDA UNS C76700 SCRAP / NICKEL SILVER CDA UNS C76700 BAR / NICKEL SILVER CDA UNS C76700 PLATE

- NICKEL SILVER CDA UNS C77000 SCRAP / NICKEL SILVER CDA UNS C77000 BAR / NICKEL SILVER CDA UNS C77000 PLATE

- NICKEL SILVER CDA UNS C79000 SCRAP / NICKEL SILVER CDA UNS C79000 BAR / NICKEL SILVER CDA UNS C79000 PLATE

- NICKEL SILVER CDA UNS C77400 SCRAP / NICKEL SILVER CDA UNS C77400 BAR / NICKEL SILVER CDA UNS C77400 PLATE

- NICKEL SILVER CDA UNS C77600 SCRAP / NICKEL SILVER CDA UNS C77600 BAR / NICKEL SILVER CDA UNS C77600 PLATE

- NICKEL SILVER CDA UNS C78200 SCRAP / NICKEL SILVER CDA UNS C78200 BAR / NICKEL SILVER CDA UNS C78200 PLATE

- NICKEL SILVER CDA UNS C78270 SCRAP / NICKEL SILVER CDA UNS C78270 BAR / NICKEL SILVER CDA UNS C78270 PLATE

- NICKEL SILVER CDA UNS C79800 SCRAP / NICKEL SILVER CDA UNS C79800 BAR / NICKEL SILVER CDA UNS C79800 PLATE

- NICKEL SILVER CDA UNS C97300 SCRAP / NICKEL SILVER CDA UNS C97300 BAR / NICKEL SILVER CDA UNS C97300 PLATE

- NICKEL SILVER CDA UNS C97400 SCRAP / NICKEL SILVER CDA UNS C97400 BAR / NICKEL SILVER CDA UNS C97400 PLATE

- NICKEL SILVER CDA UNS C97800 SCRAP / NICKEL SILVER CDA UNS C97800 BAR / NICKEL SILVER CDA UNS C97800 PLATE

- Nickel Copper Scrap

- NICKEL COPPER CDA UNS C96950 SCRAP / NICKEL COPPER CDA UNS C96950 BAR / NICKEL COPPER CDA UNS C96950 PLATE

- NICKEL COPPER CDA UNS C96300 SCRAP / NICKEL COPPER CDA UNS C96300 BAR / NICKEL COPPER CDA UNS C96300 PLATE

- NICKEL COPPER CDA UNS C70252 SCRAP / NICKEL COPPER CDA UNS C70252 BAR / NICKEL COPPER CDA UNS C70252 PLATE

- NICKEL COPPER CDA UNS C70100 SCRAP / NICKEL COPPER CDA UNS C70100 BAR / NICKEL COPPER CDA UNS C70100 PLATE

- NICKEL COPPER CDA UNS C70250 SCRAP / NICKEL COPPER CDA UNS C70250 BAR / NICKEL COPPER CDA UNS C70250 PLATE

- NICKEL COPPER CDA UNS C70310 SCRAP / NICKEL COPPER CDA UNS C70310 BAR / NICKEL COPPER CDA UNS C70310 PLATE

- NICKEL COPPER CDA UNS C71300 SCRAP / NICKEL COPPER CDA UNS C71300 BAR / NICKEL COPPER CDA UNS C71300 PLATE

- NICKEL COPPER CDA UNS C70200 SCRAP / NICKEL COPPER CDA UNS C70200 BAR / NICKEL COPPER CDA UNS C70200 PLATE

- NICKEL COPPER CDA UNS C70270 SCRAP / NICKEL COPPER CDA UNS C70270 BAR / NICKEL COPPER CDA UNS C70270 PLATE

- NICKEL COPPER CDA UNS C71500 SCRAP / NICKEL COPPER CDA UNS C71500 BAR / NICKEL COPPER CDA UNS C71500 PLATE

- NICKEL COPPER CDA UNS C70230 SCRAP / NICKEL COPPER CDA UNS C70230 BAR / NICKEL COPPER CDA UNS C70230 PLATE

- NICKEL COPPER CDA UNS C70240 SCRAP / NICKEL COPPER CDA UNS C70240 BAR / NICKEL COPPER CDA UNS C70240 PLATE

- NICKEL COPPER CDA UNS C70260 SCRAP / NICKEL COPPER CDA UNS C70260 BAR / NICKEL COPPER CDA UNS C70260 PLATE

- NICKEL COPPER CDA UNS C70265 SCRAP / NICKEL COPPER CDA UNS C70265 BAR / NICKEL COPPER CDA UNS C70265 PLATE

- NICKEL COPPER CDA UNS C70275 SCRAP / NICKEL COPPER CDA UNS C70275 BAR / NICKEL COPPER CDA UNS C70275 PLATE

- NICKEL COPPER CDA UNS C70290 SCRAP / NICKEL COPPER CDA UNS C70290 BAR / NICKEL COPPER CDA UNS C70290 PLATE

- NICKEL COPPER CDA UNS C70280 SCRAP / NICKEL COPPER CDA UNS C70280 BAR / NICKEL COPPER CDA UNS C70280 PLATE

- NICKEL COPPER CDA UNS C70370 SCRAP / NICKEL COPPER CDA UNS C70370 BAR / NICKEL COPPER CDA UNS C70370 PLATE

- NICKEL COPPER CDA UNS C70400 SCRAP / NICKEL COPPER CDA UNS C70400 BAR / NICKEL COPPER CDA UNS C70400 PLATE

- NICKEL COPPER CDA UNS C71100 SCRAP / NICKEL COPPER CDA UNS C71100 BAR / NICKEL COPPER CDA UNS C71100 PLATE

- NICKEL COPPER CDA UNS C71520 SCRAP / NICKEL COPPER CDA UNS C71520 BAR / NICKEL COPPER CDA UNS C71520 PLATE

- NICKEL COPPER CDA UNS C71700 SCRAP / NICKEL COPPER CDA UNS C71700 BAR / NICKEL COPPER CDA UNS C71700 PLATE

- NICKEL COPPER CDA UNS C72420 SCRAP / NICKEL COPPER CDA UNS C72420 BAR / NICKEL COPPER CDA UNS C72420 PLATE

- NICKEL COPPER CDA UNS C72500 SCRAP / NICKEL COPPER CDA UNS C72500 BAR / NICKEL COPPER CDA UNS C72500 PLATE

- NICKEL COPPER CDA UNS C70500 SCRAP / NICKEL COPPER CDA UNS C70500 BAR / NICKEL COPPER CDA UNS C70500 PLATE

- NICKEL COPPER CDA UNS C70610 SCRAP / NICKEL COPPER CDA UNS C70610 BAR / NICKEL COPPER CDA UNS C70610 PLATE

- NICKEL COPPER CDA UNS C70620 SCRAP / NICKEL COPPER CDA UNS C70620 BAR / NICKEL COPPER CDA UNS C70620 PLATE

- NICKEL COPPER CDA UNS C70600 SCRAP / NICKEL COPPER CDA UNS C70600 BAR / NICKEL COPPER CDA UNS C70600 PLATE

- NICKEL COPPER CDA UNS C70700 SCRAP / NICKEL COPPER CDA UNS C70700 BAR / NICKEL COPPER CDA UNS C70700 PLATE

- NICKEL COPPER CDA UNS C70800 SCRAP / NICKEL COPPER CDA UNS C70800 BAR / NICKEL COPPER CDA UNS C70800 PLATE

- NICKEL COPPER CDA UNS C72200 SCRAP / NICKEL COPPER CDA UNS C72200 BAR / NICKEL COPPER CDA UNS C72200 PLATE

- NICKEL COPPER CDA UNS C96600 SCRAP / NICKEL COPPER CDA UNS C96600 BAR / NICKEL COPPER CDA UNS C96600 PLATE

- NICKEL COPPER CDA UNS C70690 SCRAP / NICKEL COPPER CDA UNS C70690 BAR / NICKEL COPPER CDA UNS C70690 PLATE

- NICKEL COPPER CDA UNS C71580 SCRAP / NICKEL COPPER CDA UNS C71580 BAR / NICKEL COPPER CDA UNS C71580 PLATE

- NICKEL COPPER CDA UNS C71590 SCRAP / NICKEL COPPER CDA UNS C71590 BAR / NICKEL COPPER CDA UNS C71590 PLATE

- NICKEL COPPER CDA UNS C71581 SCRAP / NICKEL COPPER CDA UNS C71581 BAR / NICKEL COPPER CDA UNS C71581 PLATE

- NICKEL COPPER CDA UNS C96900 SCRAP / NICKEL COPPER CDA UNS C96900 BAR / NICKEL COPPER CDA UNS C96900 PLATE

- NICKEL COPPER CDA UNS C72800 SCRAP / NICKEL COPPER CDA UNS C72800 BAR / NICKEL COPPER CDA UNS C72800 PLATE

- NICKEL COPPER CDA UNS C72900 SCRAP / NICKEL COPPER CDA UNS C72900 BAR / NICKEL COPPER CDA UNS C72900 PLATE

- NICKEL COPPER CDA UNS C71000 SCRAP / NICKEL COPPER CDA UNS C71000 BAR / NICKEL COPPER CDA UNS C71000 PLATE

- NICKEL COPPER CDA UNS C72150 SCRAP / NICKEL COPPER CDA UNS C72150 BAR / NICKEL COPPER CDA UNS C72150 PLATE

- NICKEL COPPER CDA UNS C72950 SCRAP / NICKEL COPPER CDA UNS C72950 BAR / NICKEL COPPER CDA UNS C72950 PLATE

- NICKEL COPPER CDA UNS C72650 SCRAP / NICKEL COPPER CDA UNS C72650 BAR / NICKEL COPPER CDA UNS C72650 PLATE

- NICKEL COPPER CDA UNS C72700 SCRAP / NICKEL COPPER CDA UNS C72700 BAR / NICKEL COPPER CDA UNS C72700 PLATE

- NICKEL COPPER CDA UNS C73100 SCRAP / NICKEL COPPER CDA UNS C73100 BAR / NICKEL COPPER CDA UNS C73100 PLATE

- NICKEL COPPER CDA UNS C96200 SCRAP / NICKEL COPPER CDA UNS C96200 BAR / NICKEL COPPER CDA UNS C96200 PLATE

- NICKEL COPPER CDA UNS C96700 SCRAP / NICKEL COPPER CDA UNS C96700 BAR / NICKEL COPPER CDA UNS C96700 PLATE

- NICKEL COPPER CDA UNS C96400 SCRAP / NICKEL COPPER CDA UNS C96400 BAR / NICKEL COPPER CDA UNS C96400 PLATE

- NICKEL COPPER CDA UNS C96800 SCRAP / NICKEL COPPER CDA UNS C96800 BAR / NICKEL COPPER CDA UNS C96800 PLATE

- NICKEL COPPER CDA UNS C96970 SCRAP / NICKEL COPPER CDA UNS C96970 BAR / NICKEL COPPER CDA UNS C96970 PLATE

- NICKEL COPPER CDA UNS C71640 SCRAP / NICKEL COPPER CDA UNS C71640 BAR / NICKEL COPPER CDA UNS C71640 PLATE

- NICKEL COPPER CDA UNS C70350 SCRAP / NICKEL COPPER CDA UNS C70350 BAR / NICKEL COPPER CDA UNS C70350 PLATE

- NICKEL COPPER CDA UNS C71900 SCRAP / NICKEL COPPER CDA UNS C71900 BAR / NICKEL COPPER CDA UNS C71900 PLATE

- Catalytic Converter Scrap

- Steel Bar

- Home Page

- Company Profile

- Contact Us

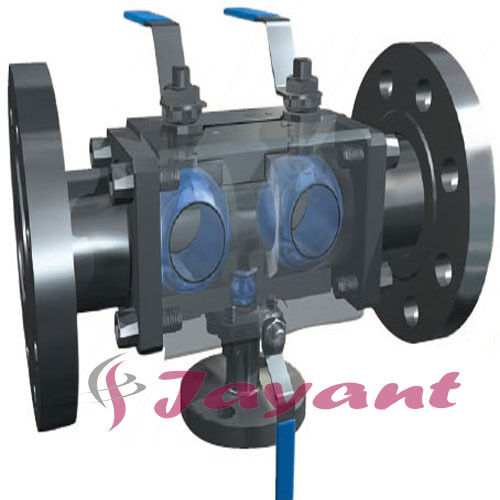

Electric Valve Actuators

Product Details:

- Application Materials handling for operations such as servo presses and clamping and widely used in the packaging sector.

- Media Water, Gas, Oil, Acid, Base

- Product Type Electric Valve Actuators

- Click to view more

-

Share Your Product:

X

Electric Valve Actuators Price And Quantity

- 1 Number

Electric Valve Actuators Product Specifications

- Materials handling for operations such as servo presses and clamping and widely used in the packaging sector.

- Water, Gas, Oil, Acid, Base

- Electric Valve Actuators

Electric Valve Actuators Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Month

- 4 Week

- Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Australia, Africa

- All India

Product Description

Electric quarter-turn valve actuators are electro-mechanical devices that are used to remotely control quarter-turn valves, such as ball and butterfly valves. Compared to their pneumatic and hydraulic counterparts, electric valve actuators provide a more energy-efficient, clean, and quiet method of valve controlAdvanced Automation for Packaging and Materials Handling

Electric valve actuators streamline industrial operations by providing accurate and automated valve control in servo presses and clamping, which are vital in materials handling and packaging industries. Their ability to manage various media enhances process safety and efficiency, making them an indispensable choice for modern manufacturing facilities.

Reliable Solutions for Diverse Media Applications

Designed to handle a range of fluids and gases, including water, oil, gas, acid, and base, electric valve actuators serve broad industrial needs. Their robust construction ensures long-term performance and minimal maintenance, reducing downtime and overall operational costs for users across sectors.

FAQs of Electric Valve Actuators:

Q: How do electric valve actuators improve operations in materials handling and packaging industries?

A: Electric valve actuators automate and accurately control the movement of valves, enabling efficient process management in materials handling tasks such as servo presses and clamping. In the packaging sector, they facilitate precise control for fluid and gas flow, thus increasing productivity and reducing manual intervention.Q: What media are electric valve actuators suitable for controlling?