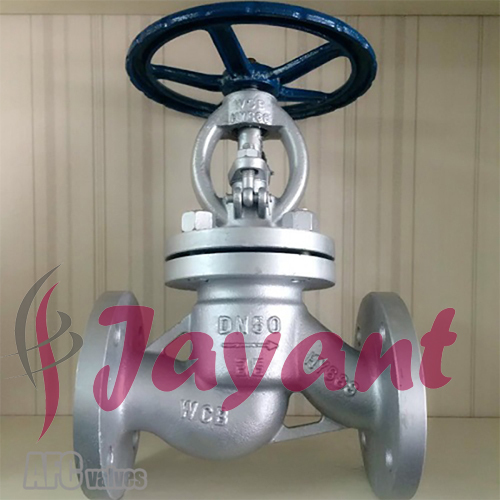

Din Globe Valves

Product Details:

- Application Cooling water systems. Fuel oil systems. Feedwater or chemical feed systems. Boiler and main steam vents and drains. Turbine lube oil system and others.

- Size DN15-DN50

- Product Type Din Globe Valves

- Media Water, Gas, Oil, Base, Acid

- Click to view more

X

Din Globe Valves Price And Quantity

- 1 Number

Din Globe Valves Product Specifications

- Cooling water systems. Fuel oil systems. Feedwater or chemical feed systems. Boiler and main steam vents and drains. Turbine lube oil system and others.

- Water, Gas, Oil, Base, Acid

- DN15-DN50

- Din Globe Valves

Din Globe Valves Trade Information

- Nhava sheva

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- 100 Number Per Week

- 3 Week

- Central America, North America, South America, Western Europe, Middle East, Eastern Europe, Asia, Australia, Africa

- All India

Product Description

It is a casted full bore valve, inside screw, different types of plug and suitable especially for regulation, manufactured according DIN standard

1. Stem: Forged steel, single-part construction, ACME screw

2. Body-bonnet gasket: 150-600 LB graphite + stainless steel spiral wound gasket. 900 LB ring join type bonnet

3. Body and bonnet: high quality and precision tooled cast iron. Single-part bonnet

4. Backseat for on-line maintenance

5. Rising wheel

Versatility and Application

DIN Globe Valves offer excellent adaptability across multiple media, including water, gas, oil, acid, and base. Their enduring efficiency makes them a favored choice in applications such as cooling water circuits, fuel oil pipelines, feedwater systems, boiler vents and drains, as well as lubrication systems for turbines. Their compatibility with various process streams highlights their value in industrial settings.

Precision Flow Control

These valves are designed to provide meticulous regulation and shut-off, making them integral to systems that require accurate control of flow rates. The globe design ensures minimal leakage and permits efficient throttling, reducing maintenance needs and operational downtime. Their engineering complies with strict DIN standards, guaranteeing quality and reliability.

FAQs of Din Globe Valves:

Q: How are DIN Globe Valves typically used in industrial applications?

A: DIN Globe Valves are extensively used for regulating and isolating the flow of water, gas, oil, acids, and bases in systems such as cooling water networks, chemical feed pipelines, boiler and steam openings, and turbine lubrication circuits. Their precise flow-control capability makes them ideal for applications where accurate modulation is required.Q: What benefits do DIN Globe Valves offer compared to other valve types?

A: These valves provide superior shut-off, accurate flow control, and reliable performance across a wide spectrum of media. Their construction according to stringent DIN standards ensures durability and minimal maintenance, making them a cost-effective solution for demanding industrial environments.Q: When should DIN Globe Valves be selected in process systems?

A: They are best chosen when a system requires precise throttling or shut-off, especially in critical applications involving varying pressures or aggressive media. Their sturdy construction and reliability make them suitable for both routine operations and safety-critical installations.Q: Where are DIN Globe Valves manufactured and supplied from in India?

A: DIN Globe Valves are manufactured by several certified producers in India and are available through a wide network of dealers, distributors, exporters, suppliers, and traders. As a reputed participant in the Indian valve market, we ensure prompt delivery and technical support nationwide.Q: What is the process for selecting the correct DIN Globe Valve size for an application?

A: Valve size selection depends on the required flow rate, media type, and system pressure. For applications within DN15 to DN50, it is important to assess piping dimensions and required Cv values to ensure optimal valve performance. Consulting with experienced manufacturers or suppliers can help determine the most suitable specification.Q: How does the design of DIN Globe Valves benefit system reliability?

A: The globe design offers a streamlined internal path that prevents turbulence and promotes stable flow. This minimizes wear and tear, extending the valves service life and ensuring system reliability even in continuous-operation scenarios.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free