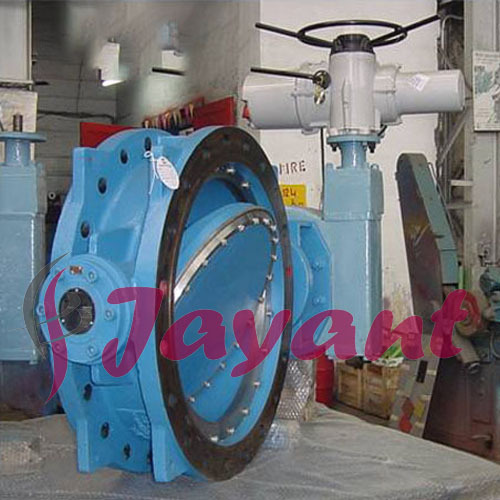

Alloy Butterfly Valve

85000 INR/Number

Product Details:

- Usage shut-off flow

- Size DN40-DN1200

- Product Type Alloy Butterfly Valve

- Color ANY COLOUR

- Click to view more

X

Alloy Butterfly Valve Price And Quantity

- 85000.00 - 250000.00 INR/Number

- 85000 INR/Number

- 1 Number

Alloy Butterfly Valve Product Specifications

- ANY COLOUR

- DN40-DN1200

- Alloy Butterfly Valve

- shut-off flow

Alloy Butterfly Valve Trade Information

- Nhava sheva

- 50 Number Per Week

- 4 Days

- As per client requirement

- Central America, North America, South America, Western Europe, Middle East, Africa, Eastern Europe, Asia, Australia

- All India

Product Description

The Alloy butterfly valve is light in weight, relatively small, relatively quick-acting, provides positive shut-off, and can be used for throttling. The butterfly valve has a body, a resilient seat, a butterfly disk, a stem, packing, a notched positioning plate, and a handleVersatile Material Selection

Choose from a wide range of advanced alloys, including Aluminum Bronze, Duplex, Hastelloy, and Super Duplex, tailored for optimal durability and corrosion resistance in demanding industrial environments. These materials ensure the valves longevity and chemical compatibility, making it suitable for sensitive and aggressive media.

Robust Performance for High-Pressure Systems

Engineered for high-pressure operation, the butterfly valve provides secure shut-off capabilities, safeguarding processes in sectors where reliability is paramount. Its manual operation gives users direct control over flow regulation, enhancing operational safety and flexibility.

Broad Industrial Applicability

From pharmaceuticals to power plants, this valve adapts to diverse requirements due to its customizable design and various alloy compositions. Its capacity to manage water, oil, gas, acids, and bases allows seamless integration with multiple fluid systems, supporting efficient production and process control.

FAQs of Alloy Butterfly Valve:

Q: How does the Alloy Butterfly Valve operate in high-pressure environments?

A: The Alloy Butterfly Valve utilizes a resilient butterfly-style structure and selected alloy compositions to maintain a reliable seal, even under high pressure. Manual operation allows precise control, making it ideal for critical shut-off flows in industries like pharmaceuticals and hydroelectric power plants.Q: What media can be managed using this valve?

A: This valve is suitable for regulating water, gas, oil, acid, and base flows, adapting to the requirements of various sectors such as chemical, food processing, and energy production, thanks to its robust material options and design.Q: When should I choose an Alloy Butterfly Valve for my process?

A: Select an Alloy Butterfly Valve when your application demands corrosion resistance, high-pressure tolerance, and compatibility with aggressive or sensitive fluids in industrial environments. Its range in sizes and alloys ensures proper fit for many systems.Q: Where can I source Alloy Butterfly Valves in India?

A: You can obtain these valves from reputable dealers, distributors, exporters, fabricators, manufacturers, and suppliers throughout India. Many retailers and wholesalers also stock various sizes, colors, and alloy types, accommodating both specialized and bulk requirements.Q: What is the fabrication process for this butterfly valve?

A: Fabrication involves precision engineering using selected alloys like Alloy 20, Inconel, or Super Duplex, followed by rigorous testing and customization (including color and size adjustments). Manufacturers ensure each valve meets operational and safety standards before supplying them to clients.Q: How does a manual butterfly valve benefit industrial fluid management?

A: Manual operation allows on-site personnel to directly control the flow, enabling quick response during emergencies or maintenance. This improves safety, regulation accuracy, and process integrity in high-pressure or sensitive operational environments.Q: What are the usage benefits for pharmaceutical and chemical applications?

A: The valves corrosion-resistant alloys and secure sealing performance help prevent contamination and uphold process reliability. Its adaptability to acids, bases, and other active media supports safe, compliant operations in pharmaceutical and chemical production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free