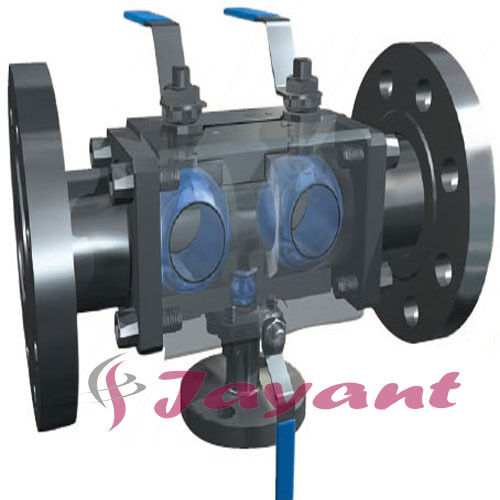

Air cushion valves

95000 INR/Number

Product Details:

- Application Air Cushion Valves is to allow large quantities of air in the pumping main during separation

- Size 50mm to 300mm

- Pressure Medium Pressure

- Product Type Air cushion valves

- Media Gas, Base, Water, Oil, Acid

- Color Multiple

- Click to view more

X

Air cushion valves Price And Quantity

- 85000.00 - 800000.00 INR/Number

- 1 Number

- 95000 INR/Number

Air cushion valves Product Specifications

- Multiple

- Air Cushion Valves is to allow large quantities of air in the pumping main during separation

- Air cushion valves

- Medium Pressure

- Gas, Base, Water, Oil, Acid

- 50mm to 300mm

Air cushion valves Trade Information

- Nhava Sheva

- Cash Advance (CA), Delivery Point (DP), Letter of Credit (L/C)

- 2 Number Per Week

- 6 Week

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

The principle of this Air Cushion Valves is to allow large quantities of air in the pumping main during separation, entrap the air, compressed it with the returning air column and expel the air under controlled pressure so as to dissipate the energy of the returning water column. An air cushion valve is thus provided

SIZE:50mm to 300mm

PRESSURE RATING : PN10/PN16/PN 20/PN 25

Versatile Media Compatibility

Air cushion valves are crafted to handle a diverse range of media such as gas, base, water, oil, and acid, making them suitable for varied industrial tasks. Their robust design and material selection ensure long-term performance and resistance to corrosion, enhancing operational reliability in challenging environments.

Wide Size and Color Range

With sizes available from 50mm to 300mm and in multiple color options, these valves offer flexibility for system designers and maintenance teams. The selectable sizing ensures that the valves can accommodate different pipeline and process requirements, while color choices may assist in quick identification or system coding.

FAQs of Air cushion valves:

Q: How do air cushion valves function in pumping main separation?

A: Air cushion valves are installed on pumping mains to manage the release and intake of air during the separation process. They prevent vacuum conditions by admitting large volumes of air quickly and safely, which safeguards system components from pressure fluctuations.Q: What are the key benefits of using air cushion valves for various media?

A: These valves can efficiently regulate the flow of different media such as gas, water, oil, base, and acid. Their compatibility with multiple substances allows use in various industries, reducing the need for separate valve types and simplifying maintenance.Q: When should I consider installing an air cushion valve?

A: Air cushion valves should be installed when there is a risk of air accumulation or vacuum conditions in pipelines, especially during rapid changes in flow or pump separation. This is critical to maintaining uninterrupted and safe pipeline operation.Q: Where can air cushion valves be used within industrial setups?

A: They can be installed in pumping stations, main pipelines, and any industrial environment requiring efficient air management. Their robust design suits numerous facilities across India, including water treatment plants, oil refineries, and chemical processing units.Q: What is the process for selecting the right air cushion valve size?

A: To choose the correct size, consider the pipeline diameter, expected flow rates, and the type of media being managed. Sizes range from 50mm to 300mm, allowing for precise matching to your systems specifications.Q: How does the color variety benefit users or installation teams?

A: Having multiple color options helps in quickly identifying specific valves during maintenance or emergency situations, enabling efficient management and reducing the time required for repairs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free